Adding a Trailer Hitch to Your Electric Vehicle Pros Cons and Considerations

7 Types Of Trailer Hitches: How To Pick The Best Hitch For Your Vehicle

When it comes to towing trailers, there is no one-size-fits-all solution. Every vehicle is different, and therefore requires a different type of hitch in order to tow safely and efficiently. In this guide, we will discuss the different types of trailer hitches available and how to pick the best hitch for your vehicle.

Types Of Trailer Hitches

There are so many different applications and uses for towing and so many different vehicle and vehicle types out there that the types of hitches available has grown to meet demand over the years.

There are 7 common types of trailer hitches well be covering in todays guide:

- Rear Receiver Hitch (Class 1-5)

- Bumper Hitch

- Weight Distribution Hitch

- 5th Wheel Hitch

- Gooseneck Hitch

- Pintle Hitch

- Front Mount Hitch

Well go through the pros and cons of each hitch type below, as well as what each is best used for.

Rear Receiver Hitch (Class 1-5)

Rear receiver hitches are the most common type of hitch available and can be found on almost any vehicle.

They are classified by their weight capacity, with Class I (Class 1) being the lightest duty and Class V (Class 5) being the heaviest duty.

Receiver hitch sizes increase with the Class number.

Rear receiver hitches are very versatile and can be used for a variety of towing applications, including bike racks, cargo carriers, and trailer lights.

They are also relatively easy to install, making them a great option for those who are not mechanically inclined.

A receiver hitch features a square tube on the end that accepts different towing accessories, such as bike racks or trailer ball mounts.

Rear receiver hitches are great for use with nearly any type of towable ranging from a hitch cargo basket, jet ski trailer, pop-up campers, boat and utility trailers, all the way to full-size travel trailers.

Weve put together a guide on parts of a trailer hitch for receiver hitches since theyre so common, so check that out if you have or are considering a rear receiver hitch.

Bumper Hitch

A bumper hitch is a type of hitch that mounts to the rear bumper of a vehicle.

These hitches are also quite common because theyre easy to install and are attached directly to the bumper of almost any vehicle.

This provides a square tube like a rear receiver hitch does for use with towing ball mounts or other towing accessories.

The receiver insert sizes range from 1-1/4 to 3 and can provide between 2,000 to 21,000 lbs of max towing capacity.

The key limitation here is that this hitch can only tow as much weight as your bumper can.

Because of this, bumper hitches are typically used for lighter loads, such as bike racks, small trailers, or pop-up campers.

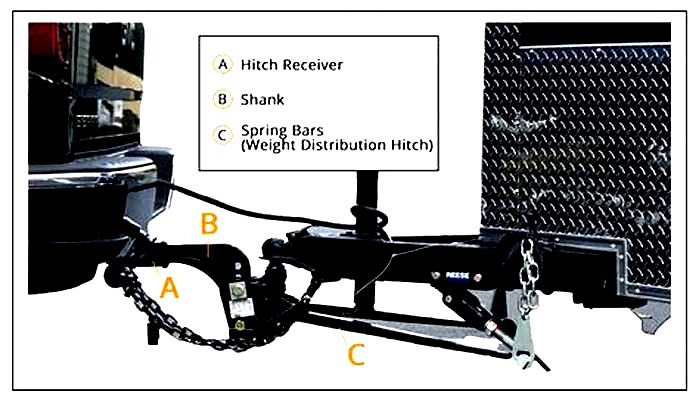

Weight Distribution Hitch

A weight distribution hitch is a type of trailer hitch that is used to distribute the tongue weight of a trailer evenly across the axle of a vehicle.

Another name for this type of hitch is a sway control hitch.

Weight distribution hitches utilize long rods called spring rods which provide leverage against the connection point to reduce the downward tongue weight at the connection point.

This is important because it helps to prevent sag and increases stability while towing.

Weight distribution hitches are typically used for heavier trailers, such as travel trailers or fifth-wheel trailers.

These hitches are more complex than bumper hitches or rear receiver hitches, and therefore can be more difficult to install.

However, once installed properly, a weight distribution hitch provides a much smoother ride while towing and can be a great option for those who frequently tow heavy loads.

Its important to note that weight distribution hitches typically arent standalone, and are usually mounted to a rear receiver hitch.

Theyre still classified as a type of hitch anyway, but are also referred to as hitch stabilizers.

5th Wheel Hitch

A fifth wheel hitch is a type of hitch that mounts in the bed of a pickup truck and is used to tow a fifth wheel trailer.

Fifth wheel trailers are typically larger and heavier than travel trailers, and as such require a more heavy-duty hitch for towing.

Fifth wheel hitches mount directly to the frame of a pickup truck near the rear axle and provide a strong connection point for towing.

The connection is a little like the opposite of a trailer ball, where the 5th wheel hitch has a U-shape mechanism with locking jaws that closes around a kingpin on the trailer.

These hitches can provide up to 30,000 lbs of max towing capacity, making them ideal for use with large fifth wheel trailers.

Installing a fifth wheel hitch can be more difficult than other types of hitches because it requires drilling into the bed of the truck.

However, once installed properly, a fifth wheel hitch provides a very stable connection for towing even the heaviest of loads.

Its important to note that 5th wheel hitches are only available for pickup trucks.

Gooseneck Hitch

A gooseneck hitch is a type of trailer hitch that mounts to the bed of a pickup truck and is used to tow a gooseneck trailer.

Gooseneck trailers are similar to fifth wheel trailers in that they are typically larger and heavier than travel trailers.

However, unlike fifth wheel hitches, gooseneck hitches mount directly to the frame of the truck near the cab.

This provides a shorter distance between the connection point and the trailer axle, which helps to improve stability while towing.

Gooseneck hitches look like a trailer ball protruding from the bed of the truck, which is where the gooseneck trailer coupler sits on.

Gooseneck hitches can provide up to 30,000 lbs of max towing capacity, making them ideal for use with large gooseneck trailers.

Installing a gooseneck hitch can be more difficult than other types of hitches because it also requires drilling into the bed of the truck.

A gooseneck hitch provides a very stable connection for towing even the heaviest of loads.

Just like 5th wheel hitches, gooseneck hitches are only available for pickup trucks.

Youll see gooseneck hitches most often used with car haulers, large flatbeds, livestock trailers, or other industrial and commercial trailers.

Pintle Hitch

A pintle hitch is a type of hitch that uses a pin and collar system for towing.

Pintle hitches are typically used for heavy-duty towing applications, such as with military trailers or construction equipment.

The pintle hitch consists of a large metal pin (the pintle) that inserts into a receiver on the vehicle, and a ring (called the lunette), which that secures the pin in place.

Pintle hitches provide up to 60,000 lbs of max towing capacity and are commonly found on dump trucks, construction and industrial equipment, agricultural applications, and even military vehicles.

They allow for a wider range of motion than a tow ball, which makes them better for off-road use like construction or farming.

Front Mount Hitch

A front mount hitch is similar to a rear receiver hitch, except it is bolted to the frame in the front of your vehicle.

Beyond that, the look is pretty similar, with a receiver tube that accepts different accessories.

Common uses for front mount hitches area snow plows, winches, spare tire mounts, cargo baskets, and more.

Front mounts are usually rated for less weight than rear receiver hitches.

Different Types Of Trailer Hitches: Wrapping Things Up

Youll see trailer hitches on every type of vehicle.

There are many different types of hitches available on the market today.

Each type of hitch is designed for a specific purpose and has its own set of advantages and disadvantages.

When choosing a hitch, its important to consider your vehicles towing capacity, what youll be using it for, and how much weight youll be towing.

With so many options available, theres sure to be a hitch thats perfect for your needs.

The Pros and Cons of Using Electric Vehicles in Your Fleet

Fleet management and planning for electric vehicle deployment.

The time has finally arrived with the continual shift toward electrification picking up serious traction, the transition to electric vehicle (EV) fleets is underway. With the right implementation strategy, electric vehicles have the power to optimize your fleets productivity and take your business to new heights.

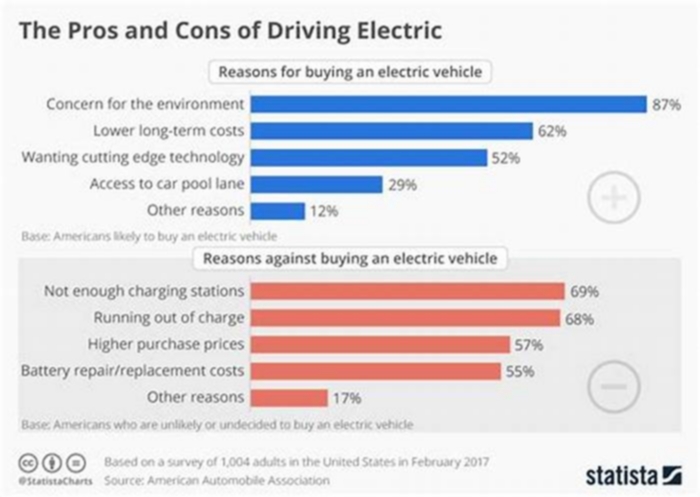

Wondering if you should start using electric vehicles in your fleet? In this article, were covering the essentials behind the EV markets explosive growth and sharing the most notable pros and cons of fleet electrification.

Fleet Electrification

You may be wondering, why now? Electric vehicles have been around for years without impacting fleets! Groundbreaking technology in the industry has recently evolved to include electric trucks and vans, thus revolutionizing fleets of any size or operation.

Additional electric vehicle trends sparking the demand for fleet electrification include:

1. Increased Availability and Diversity of EV Models

EVs were previously overlooked by the fleet industry due to the lack of EV models for work trucks. It was especially atypical to see EVs as an option among the secondary markets such as those for used cargo vans.

However, major OEMs such as Ford and GM have committed to producing a wide array of new EV models. The EV market is soon to be flooded with product launches that will include pick-up trucks, cargo vans, and even long-haul vehicles.

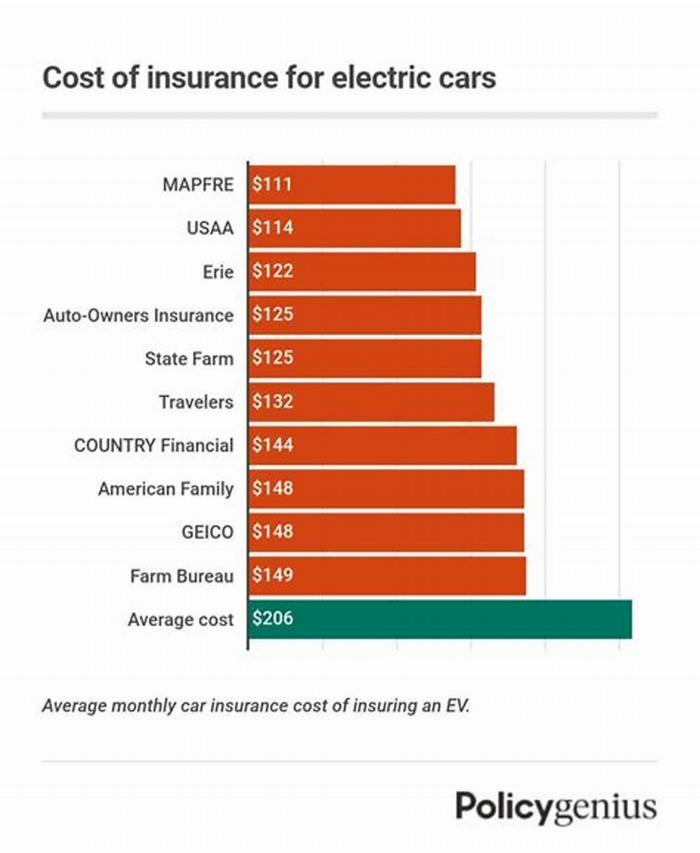

2. Reduced Cost of Ownership

Upon their initial rollout, one of the major hurdles to acquiring an EV was the high cost of ownership. In recent years the prices of EVs have gone down as a result of battery cost reduction and they are continuing to trend downwards.

3. Increased Sustainability Policies and Incentives

The threat of climate change has served as a call for intervention, especially within the automotive industry. Both local and federal governments are beginning to incentivize the adoption of electric vehicles, such as the federal income tax incentive of $7,500 per eligible EV.

Another example includes the state of Californias announcement to ban the sale of new gas cars by 2035, excluding medium- and heavy-duty vehicles such as trucks and construction equipment, which will need to be zero-emission by 2045.

4. Increased Focus on Corporate Social Responsibility

Consumer expectations have shifted to place a strong emphasis on social matters, making it more important than ever to possess definitive commitments to corporate social responsibility. Many companies are diving into the process of reducing their carbon footprint by transitioning their fleets to EVs.

Pros of Using EVs in Your Fleet

There are numerous advantages to using electric vehicles in your fleet, including:

1. Sustainability

By using EVs in your fleet, you will demonstrate your commitment to corporate social responsibility through the reduction of pollution and emissions. Eliminating fuel exhaust from your fleet will in turn reduce greenhouse gas emissions.

2. Lower Fuel Costs

Fuel has traditionally been one of the highest operating costs for fleets. By operating on electricity, the cost to fuel a plug-in vehicle is significantly lower than the cost of fueling with gas or diesel. Running a fleet of EVs will dramatically decrease the total fuel costs.

3. Less Maintenance

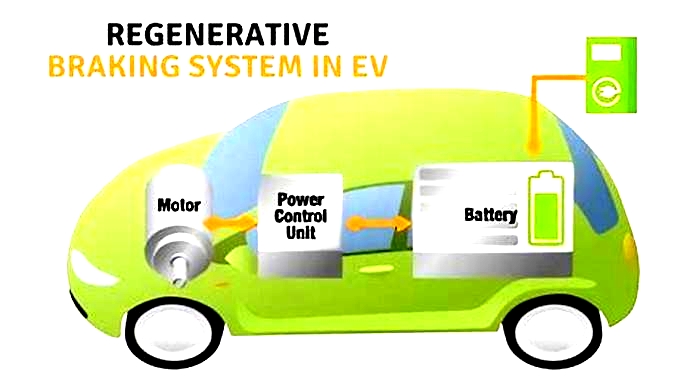

EVs require significantly less maintenance and service requirements than vehicles with engines. The reason behind this is simply that electric vehicles have uncomplicated features and fewer moving parts.

One example of this is regenerative braking, in which the vehicles kinetic energy is stored in the battery during deceleration to further be used to power the motor. This results in less brake wear and therefore longer-lasting brakes. Moreover, any services that EVs do need are typically cheaper than that of a motor vehicle.

4. Fleet Management Systems

The highly innovative technology of a fleet management system will allow you to maximize your investment through digitally connected vehicles. Features include software to determine the most efficient routes, sensors to monitor cargo and real-time charging status.

You can even view your fleets fuel energy use to set carbon emission goals and track when these goals are met.

5. Happier Employees

Commercial fleets operating with EVs have seen improved employee performance and retention. Drivers are getting a smoother, quieter ride without being surrounded by exhaust fumes. One study on EV taxis found that the quieter ride led to improved mood and lower levels of stress.

Cons of Using EVs in Your Fleet

Electric vehicles arent for every fleet. Some of the downsides that come with electric fleet vehicles include:

1. Range Constraints

On average, battery electric vehicles (BEVs) have a range between 100 and 300 miles. Ranges can vary based on the efficiency and speed of the driver, heating or cooling uses, as well as the amount of load placed on the vehicle.

Fortunately for long-haul trucking, the Tesla Semi is expected to launch by the end of 2021 and will have a range of up to 500 miles.

2. Remote Areas

Problems may arise if your fleet frequently travels though remote areas with few to no charging stations. Although many countries are taking action to put more EV charging stations in public areas, these far-off areas are likely to be the last to receive this technology.

3. Lack of Used EV Options

The flood of new EV models becoming available on the market will subsequently lead to a growing inventory of first-generation EVs within the used auto market. However, these first-generation vehicles fail to include the options that fleet owners require, such as used cargo vans or commercial work trucks.

4. Higher Upfront Cost

The initial investment in an electric vehicle is higher than gas or diesel vehicles. However, the majority of EVs will require much less maintenance than standard vehicles and will ultimately save you money in the long run.

Questions to Ask Before Fleet EV Implementation

To ensure a smooth transition to electric vehicles, be sure to make these key considerations:

- Is the adaptation to EVs feasible for my fleet vehicles?

- Are there any tax credits or incentives that my fleet could benefit from?

- Are the EVs able to be upfitted to meet my fleets needs?

- Does my fleet partner work with a wide array of OEMs to get me the models that my fleet requires?

- Where will my employees charge their vehicles? Am I able to install on-site charging?

- Does my service network have EV-trained technicians?

- Are there any opportunities for fleet remarketing?

The buzz around electric vehicles is more than just a call to improve the environment it is the way of the future. With careful research and planning, making the switch to using EVs in your fleet will prove to be a valuable asset. Fleets that plan for an electric future today are putting themselves in a position to fuel their future successes.

Photos and sketches copyright the respective manufacturers: Daimler, Workhorse, Ford, and Tesla.

serves as the VP of Operations at

Merchants Fleet. In his role, he works with various companies serving the last mile space and collaborates with last mile clients on upfitting, identifying and acquiring the right assets, fleet planning, and consulting. He also leads the commercial sales team which is selling commercial vehicles nationwide at Merchants Auto located in Hooksett, NH.

Latest posts by Marcus Luce

(see all)