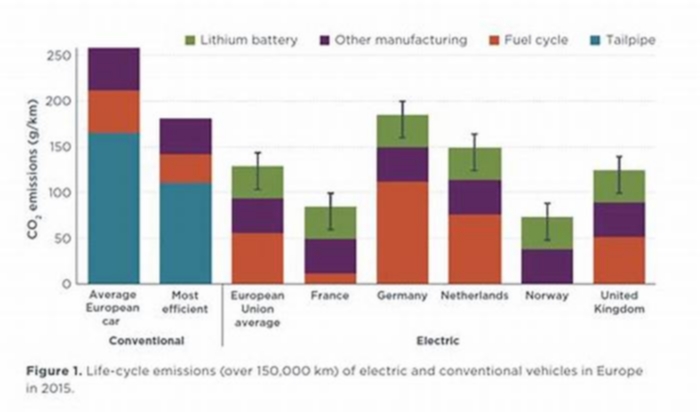

Does Tesla use BYD batteries

New Tesla Model Y with BYD batteries charges much faster

The new Tesla Model Y, built with BYD batteries at Gigafactory Berlin, charges significantly quicker than the previous version.

As we have recently reported, Tesla and BYD have developed into unlikely partners lately.

There was a time when they didnt take each other very seriously; theres an infamous interview in which Elon Musk literally laughs at BYDs electric vehicles, but they have since both emerged as EV powerhouses.

While they were mainly seen as competitors, the two companies started getting cozy together last year asTesla started to buy battery cells from BYD. Tesla is believed to be using BYDs new Blade battery, which is an LFP cell packaged in a long blade-like format.

The new Model Y with these cells recently went into production at Gigafactory Berlin, and now the Tesla fans on the local German TFF forum are already finding some interesting differences.

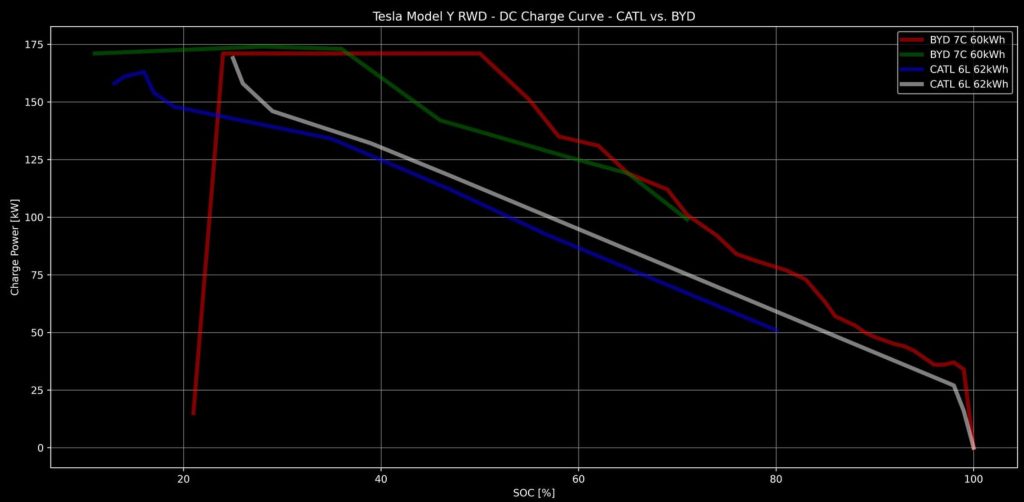

The biggest one so far is the fact that the new BYD cells appear to maintain the peak charge rate for significantly longer:

The Model Y with the new BYD cell has a similar top charge rate as the older Model Y with CATL LFP cells built at Giga Berlin.

However, the new cells appear to be able to maintain that charge rate and overall a higher charge rate through a higher state of charge. This should translate into a shorter overall charging session.

Its important to note that many factors can affect a charging session some of them have nothing to do with an electric vehicle, like the chargers themselves and the temperature.

Electreks Take

Thats an interesting early sign of better performance it looks like it is able to maintain 170 kW through 50% state-of-charge and 100 kW at about 70% state-of-charge. It should bring you up to 80% in less than 30 minutes in most cases.

So that takes care of one of the original disadvantages of LFP cells. Now potential buyers might be looking for performance in the cold, which has also been a problem with LFP cells in the past.

We are going to have to wait for the winter in Europe for that one, though.

FTC: We use income earning auto affiliate links. More.

Tesla starts utilising BYD batteries at Giga Berlin

According to industry insiders, BYD has started supplying LFP cells to Tesla, specifically to the plant in Grnheide, Germany. The first batch of Tesla Model Ys equipped with BYDs Blade batteries are expected to roll off the assembly line at Giga Berlin in a month at the earliest.

For the time being, Tesla has no plans to use BYD batteries in its China plant in Shanghai, reports the Chinese portal Sina Tech, citing several sources familiar with the events. The company will continue to install cells from CATL and LG Energy Solution there. Specifically, around 70 per cent of the battery cells installed in the Giga Shanghai come from CATL and 30 per cent from LGES.

The fact that BYD will supply LFP cells to Tesla had become apparent before rumours to this effect had started to surface in 2021, and this June, a high-ranking BYD manager essentially confirmed the information. At that time, however, it was assumed that BYD would supply Giga Shanghai.

Tesla reportedly only builds the Model Y in Grnheide so far, so BYD Blade batteries are likely to be installed in the electric SUV. Whether this is a direct replacement of the previous battery packs consisting of 2170 round cells or LFP batteries for a new type of drive is unclear from the report. However, the latter is more likely.

Until now, industry circles assumed that Tesla would introduce 4680 cells with a structural battery pack as a second battery variant in addition to the 2170 cells for the Model Y Performance and some long-range models built in the meantime. The fact that a battery version without round cells and then immediately with LFP chemistry is being introduced would be new.

BYDs Blade battery is LFP cells in a special format, they are very long and narrow. As lithium iron phosphate cells, they are free from materials such as nickel and cobalt. With the sword-like form and BYDs proprietary cell chemistry, the Blade battery pack claims higher energy density than LFP cells in a more conventional form. According to earlier reports, up to 150 Wh/kg should be possible. In addition, BYD has repeatedly emphasised the high safety of this battery design.

A major advantage of the LFP batteries apart from the fact that some critical materials are redundant is the price: the portal PushEVs writes of an estimated 55 euros per kilowatt hour, or 64 dollars/kWh for the Blade battery. Disadvantages of the technology are the lower energy density and also the power output or consumption; the charging power is usually lower than that of batteries with NCM cells.

Back in Brandenburg, Tesla wants to increase the number of employees in its Grnheide plant from the current 5,000 this month, according to information from local TV channel RBB, in order to be able to work with a second fully staffed shift. In the future, the plant will work 24 hours a day in a three-shift system.

By the first quarter of 2023, Tesla aims to increase production at Giga Berlin to 5,000 electric cars per week. To optimise processes, Tesla interrupted production in Grnheide for a fortnight in July. According to information from RBB, one of the issues was a large casting robot that manufactures the rear body part of the Model Y. Too many of the parts produced were defective.

cnevpost.com (batteries), rbb24.de (Grnheide)

Tesla is reportedly going to build Model Y with BYD blade batteries at Gigafactory Berlin

After months of rumors that Tesla is going to use BYDs blade batteries at Gigafactory Shanghai, theres a surprising turn of events that suggest Tesla is actually going to use the new battery cells at Gigafactory Berlin, and it reportedly already took delivery of the first cells.

In 2020, BYD, a China-based electric vehicle and battery company, introduced its new bladed battery cell. The new cells use LFP chemistry, but the new form factor, which looks like a blade, is the real innovation enabling a safer cell and higher energy density at the pack level, according to the company.

BYD wrote in a press release:

While undergoing nail penetration tests, the Blade Battery emitted neither smoke nor fire after being penetrated, and its surface temperature only reached 30 to 60C. Under the same conditions, a ternary lithium battery exceeded 500C and violently burned, and while a conventional lithium iron phosphate block battery did not openly emit flames or smoke, its surface temperature reached dangerous temperatures of 200 to 400C. This implies that EVs equipped with the Blade Battery would be far less susceptible to catching fire even when they are severely damaged.

While this feature obviously offers great safety advantages, it also delivers thermal management improvements, and BYD claims the form factor enables energy density improvements by eliminating the need for modules.

It goes directly from cell to pack, not unlike Teslas structural battery pack technology.

In 2021, we first heard rumors thatTesla was testing BYDs new blade batteries for a potential supply partnership last year.

When the report came out last year about Tesla testing the new cell from BYD, it stated that Tesla already had the cells in test vehicles and that it could start deliveries for production in the second quarter of 2022.

Earlier this year, BYD confirmed that it is about to start supplying Tesla (TSLA) with battery cells. It was presumed that those cells would go to Tesla Gigafactory Shanghai.

Now a new report coming from Sina says that the cells are actually going to Gigafactory Berlin and that the first vehicles with the cells could roll off of the factory within a month (translated from Chinese):

On the afternoon of August 10, a number of people familiar with the matter revealed that the blade battery supplied by BYD has been delivered to Teslas Gigafactory in Berlin, Germany, which is also Teslas first super factory to use BYD batteries. Tesla vehicles can roll off the assembly line in as little as one month (that is, the end of August to the beginning of September).It was also learned from another source that the Shanghai Gigafactory, which has attracted much attention, has no plans to use BYD batteries for the time being.

This is a surprising turn of events if it turns out to be true, but neither Tesla nor BYD are confirming right now, though BYD has previously confirmed plans to supply Tesla with battery cells.

FTC: We use income earning auto affiliate links. More.

What can the Tesla Model Y with BYD battery do?

Is the Tesla Model Y a German car? In the case of our test car, you may say yes. After all, it was produced in Grnheide, near Berlin, as indicated with a B on the license plate. At our request, the press office provided us with the basic trim, meaning a rear-wheel instead of all-wheel drive and a range of 455 instead of 533 kilometres in the WLTP cycle. It also means the model comes equipped with LFP cells from BYD in the traction battery, whose basic characteristics include sensitivity to cold. Can this work in winter, and if so, how much compromise do buyers have to accept when investing 7,000 less than what theyd pay for the full long-range?

The good news first: for 42,990 (Editors note: the car was 44,890 in Germany at the time of writing, but Tesla has since lowered the price), you get everything that makes a Tesla special. Foremost is the ease of operation. In other words, the combination of simplicity and convenience or sheer usability. Specifically, the app is error-free and shows the location, the state of charge and the interior temperature. Preconditioning is just as possible via the app as opening and closing, reliably and quickly. Unfortunately, this is worth mentioning because many competitors do not offer this or do not offer it with such clarity.

Tesla means convenience

This also applies to the navigation. After entering the destination by voice control, the display shows the Superchargers along the route and how long charging should take. At the same time, the traction battery is preconditioned for the stop, which means warmed up in winter. Once at the Supercharger, charging starts like with Plug & Charge since identification is automated. Plug in the cable, done.

It should be clear to everyone that this combination of perfect route planning, targeted preconditioning and Plug & Charge lets call it that, even if its not precisely the standardised procedure is ideal, especially for those who want to drive an electric car without having to know much. This is convenience, after all. Many competitors have understood this and adopted the principle. Some, on the other hand, offer nothing at all in this respect. (BMW caught up with Tesla in one function: manual preconditioning is a successful feature for anyone who likes to drive without a navigation system.)

Preconditioning eliminates the cold problem

The point where the Tesla Model Y RWD excels is in traction battery management. Tesla does not publish data, but according to our measurement and other consistent sources, the energy content is 60 kilowatt-hours (kWh). What Tesla is doing with BYDs LFP cells is impressive.

LFP cells (lithium iron phosphate) have one problem: In frosty conditions, they do not draw any power at all, and they only really feel comfortable at an internal temperature of over 40 degrees. Obviously, the control software is designed to achieve this target corridor through preconditioning. This also shows in the increase in power consumption before stopping at a Supercharger station.

Charging performance like 800-volt systems

The result? It reproducibly took under 20 minutes to charge from ten to 80 per cent in wintry outside temperatures of three to eight degrees. This is almost on par with Hyundais e-GMP platform with 800 volts, where the factory specification is 18 minutes.

The peak power in the Model Y is over 170 kW. However, this figure is less meaningful than looking at the time for the typical charging period from ten to 80 per cent. This makes it easier to compare the performance of traction batteries with different capacities. Experts may know this as a C-rate. And here, 20 minutes not only means a lead over the average 30 minutes the competition usually takes. This sprint also outclasses the supplier BYD, which claims 44 minutes in its electric cars, such as the Atto 3.

LFP cells are resilient

How does Tesla do this? This is open to plausible speculation. What is clear is that preconditioning is a mandatory prerequisite for the high charging speed. Tesla achieves this with extensive experience and software. Furthermore, Tesla likely expects more from LFP cells than from other cell chemistries.

The reason is that LFP cells have a very high cycle stability. If a little of this excess durability is lost because the cells are pushed hard, it may be barely noticeable. It is also essential to understand that LFP cells have a very low risk of thermal runaway, as they are quite resilient.

The Model Y is economical

The LFP cells in the Tesla Model Y RWD are not only a disadvantage but are also favourable regarding real-life range. Tesla claims 455 kilometres and a power consumption of 15.7 kWh/100km according to the WLTP standard. In the winter test, we achieved precisely 20 kWh/100km or, as the brand puts it, 200 Wh/km on average. This results in a calculated range of 300 kilometres.

Keeping within the speed limits on the motorway, we were able to determine a range of 20.2 kWh/100km in heavy traffic and with varying speeds up to 24.7 kWh/100km on a clear stretch of road and with active preconditioning. This reduces the range to 243 kilometres. However, driving faster or even up to the top speed of 217 km/h possible only in Germany is no fun. More on that in a moment.

First, a few other sample values for power consumption, 15.4 kWh/100 km, were recorded in interurban operation. The minimum value of 13.4 kWh/100km was achieved in flowing city traffic. The Tesla Model Y is economical for a car of this size.

Chassis tuning and noise insulation could be improved

It is hardly surprising that the Tesla Model Y is the best-selling car in Europe and not just among electric vehicles. It offers plenty of space, is easy to operate, and benefits from the image that Tesla enjoys nowadays. Tesla is almost synonymous with the electric car itself.

However, with a little distance and a certain sobriety, it must also be said that the Model Y has weaknesses. For example, the chassis set-up remains poor. At low speeds, the ride comfort is moderate. At higher speeds, the steering is too indifferent. And when driving fast on the motorway, the Model Y is not nearly as confident as a BMW iX1, so you would rather refrain from speeding voluntarily.

Anyone who hasnt driven a new car for years or has never travelled in an electric vehicle will hardly notice. But there is much tough competition in this segment and price range, and it is often quieter and more comfortable.

Tesla has recently focussed heavily on reducing costs in production a strategy that will pay off when the battle for money gets tougher. Leap innovations, on the other hand, have failed to materialise.

Assistance systems no longer cutting-edge

This is also the case with the autopilot, which does not fulfil what can be expected in this segment. The adaptive cruise control (neither Enhanced nor FSD) worked almost flawlessly during the test period. However, such a system in a Toyota Yaris small car does this as standard and matter-of-factly. Even in lane assist, a detail shows that Tesla has some catching up to do: The steering wheel does not recognise people by touch, but by pulling on the steering wheel. The design is also too sensitive and gives repeated warnings to put your hands on the controls even though they have been there for a long time.

The identification of lane lines and their differentiation between white and yellow, for example, in roadworks, is also not at the same level as the competition. And the traffic sign recognition system makes mistakes too often. It is only logical that there is no automatic, but only a manual transfer of the limits to the cruise control.

What is also missing is a 360-degree camera. The combination of the existing cameras does not produce a good all-round image, and the display of the centimetres to the next obstacle when parking is no longer as precise as it was in the days of Teslas ultrasonic sensors. Its better to turn your head. The test car did not yet have the Holiday Update with 3D Park Assist, which may lead to an improvement.

The Model Y is the new Golf

The Tesla Model Y RWD for 42,990 euros (44,000 GBP) is by no means without an alternative. A Volkswagen ID.4 with rear-wheel drive, a 77-kWh traction battery and a standard range of 550 kilometres costs 40,900 until 31 March. VW is asking 32,600 for the ultra-mag version of the ID.4 with 52 kWh and 364 kilometres. The BMW iX1, with 474 kilometres in WLTP, is available for 47,900. An entire armada of electric SUVs of this size competes with the Model Y, and yet it sells best.

The Tesla Model Y has replaced no other than the Volkswagen Golf in Europe. What makes the Model Y RWD attractive from our point of view is how well thought-out this electric car is in terms of its typical drive characteristics. The short charging times at the Superchargers and the reliability of the route planning are fundamental plus points. Many customers like the reduced, clean cockpit, which still has an indicator lever before the foreseeable revision called Juniper, and the operation via the display. For everyone else, there is plenty of choice from other manufacturers.

Review by Christoph M. Schwarzer, Germany. Translation and localisation by Nora Manthey, UK.