EV Fleet Management Strategies for Businesses Going Electric

Electric Vehicle (EV) Fleet Management: How to Get Operationally Ready

The global transportation sector is at a crossroads. Just as many businesses began recovering from pandemic-caused supply chain disruptions, yet another obstacle came up a call for fleet electrification from regulators and consumers alike.

As if it were so easy to just pull the plug on a petrol-fueled fleet and go electric, the average fleet manager may mutter to themselves.

Indeed, the transition to electric vehicle fleet management isnt an easy target. But its an inevitable next step well have to pull off collectively.

How will vehicle fleet electrification affect the trucking and transportation industries?

EV fleet management will require new strategies for route planning, charging, maintenance, driver upskilling, and proactive compliance reporting on carbon targets. Thats the tough part.

For many, electric fleet management feels like an externally imposed hurdle. From California to Hong Kong, governments are issuing air pollution control mandates and rigid directives for commercial fleet owners to make trucks sold in the state be emissions-free by 2035 or face heavy penalties.

But is there more to fleet electrification than just complying with regulatory demands? Of course.

While 90% of fleet managers describe fleet electrification as inevitable, 85% also see electric vehicle fleets as an opportunity to save on operational and maintenance costs.

Benefits of electric vehicle fleet management

Fleet management companies will certainly need to buckle up for major operational transformations. But when they execute on their roadmaps, a bevy of benefits will follow.

Fuel cost reductions

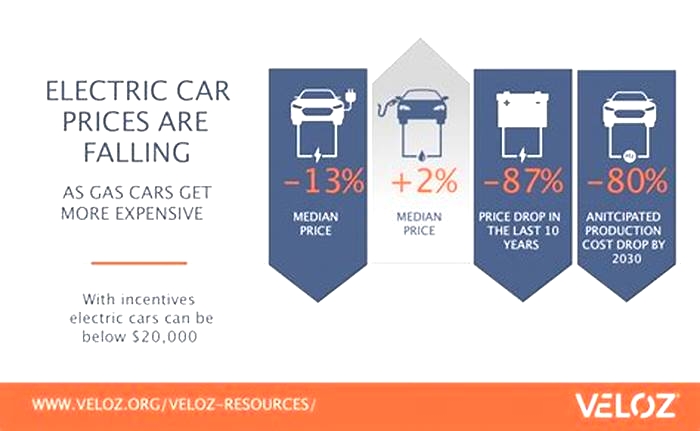

Fuel costs are still one of the biggest expenses in managers budgets, accounting for about 33% of spendings on average. Using effective fuel management solutions can help trim those. Yet the long-term savings of switching to an electric vehicle fleet (and later to alternative fuels) are still bigger.

Even today, its 43% cheaper to use electric power over gasoline for medium-duty vehicles in the top 25 US metro areas. In countries where fuel prices are higher, the savings are even more tangible. Finally, transitioning to EVs can protect your business from the turbulence of global markets.

Lower maintenance costs

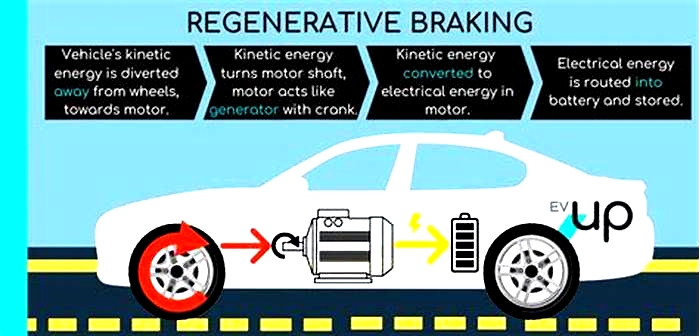

Its easy to argue that electric vehicles will be less expensive to maintain than older fleets for the first few years. But the design of electric vehicles themselves promotes a longer operational life. EVs need less fluid to function, are easier on braking, and overall have fewer moving parts that need regular maintenance.

NYC authorities have used analytics to compare how different assets in their fleet perform. They found that the average electric car maintenance bill was $386 per year vs $1,600 spent on a gas-powered car.

EV maintenance costs can also be further reduced by implementing predictive maintenance based on car-collected data. By creating digital twins of EV batteries, fleet managers can collect real-time vehicle performance data under different conditions and use it for route optimization. Lastly, as EV battery technology further evolves, maintenance costs associated with battery servicing will go down too.

Better brand perception and more business

Its not just the transportation industry being pressed by regulatory demands. Nearly every other industry now attempts to reduce their carbon footprint and provide accurate CRS data to regulators, investors, and consumers.

Completing fleet electrification early can make your operations more attractive to business partners. At the same time, it can win you extra points with consumers. Many now demand greener options. Thats not news. Whats interesting is that many people are willing to change their habits if this leads to more sustainable options.

For example, 30% of consumers who wont tolerate a longer delivery time when given economic incentives (free shipping) are willing to do so when theres an environmental incentive (carbon-neutral shipping). Thats a good reason for adopting electric last-mile solutions. Still, youll need to make difficult choices around investing in the right hardware and software to power your operations.

EV fleet management systems: Main components

When it comes to fleet electrification, most conversations are centered around hardware the best e-vehicle models, electric vehicle charging infrastructure, etc.

Sure, youll need to learn about different types of chargers (rapid or ultra-rapid DC, which is best?). But this transition also assumes a more profound redefinition of how you manage the entirety of your operations:

Source: AMPLY Managed Charging Accelerates Cost & Health Benefits of EVs

EV fleet operators will need to accommodate extra workflows in their fleet management routines:

- Energy cost management

- Optimized charging schedules

- Context-aware route planning

- Remote e-fleet monitoring and diagnostics

- Battery analytics and servicing

As a technology services company, wed like to help you prepare for this scope of changes in vehicle fleet management. To do this, weve made a list of conceptual subsystems a comprehensive EV fleet management solution should have.

EV routing system

Electric vehicle fleets have vastly different charging needs. Charging is more frequent and time-demanding than fueling a gas- or diesel-powered vehicle. So range anxiety is very real.

The average EV range is about 200 miles or 320 km more than enough for last-mile deliveries, but somewhat more limiting for long-distance transportation.

At the same time, range capabilities are vastly impacted by both individual vehicle characteristics and external conditions such as weather, road elevation, and traffic. Your EV fleet management program has to account for these factors.

How exactly? By collecting data on EV fleet utilization and using it for context-based routing.

Heres how it works.

First, youll need to build software integrations with the e-vehicles telematics to gain baseline performance analytics. Then add extra data sources such as location-based services and traffic and mapping APIs to become more aware of the surroundings and real-time driving conditions. Finally, connect all these data sources to your intelligent EV routing system that can design realistic routes using these inputs.

Some other good-to-have features for an EV routing system are:

- Range prediction module. A vehicles battery capacity and consumption determine its driving range. When driving, all sorts of dynamics impact consumption. Predictive analytics solutions can use available telematics and third-party data to provide accurate estimates for different types of vehicles and operational routes. Such solutions can be integrated from vendors or developed in-house.

- Route building around charging stations. Charging infrastructure is still scarce, so youll have to plan long-distance freights around available options. You can obtain mapping data on charging stations via public databases or purpose-built commercial APIs. Integrating this data into your route planning will ensure that your EV fleet drivers never take a detour on an extra-low battery (which can be damaging for your assets).

- Model-specific electric vehicle routing. Similarly, knowing the ranges and performance characteristics of different EVs helps you plan more realistic and efficient routes. Data on model-specific features such as support for fast charging, average charge trip range, and battery depreciation can help with fleet orchestration and support future asset purchase decisions. You can either build and maintain a personal database or opt for a commercial API.

- Context-specific performance predictions. Individual driving styles, vehicle loads, topography, and weather can act as tailwinds or headwinds. Taking these into account as well helps you obtain a more comprehensive picture of your fleet performance and implement targeted optimizations. This data can be obtained from onboard computers, ADAS, and driver monitoring solutions, plus external open APIs (e.g. traffic APIs) and GIS services.

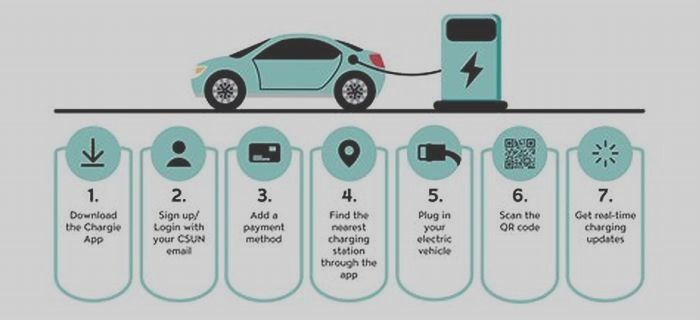

Wondering how all of the above works in real life? Heres the business logic we used when developing an electric vehicle trip planner with multi-stop routing capabilities.

Our client already had an advanced infotainment system that generated accurate range maps for e-vehicles. We used available telemetric data on standard ranges as a backbone for route planning, plus augmented it with topography and mapping data.

The EV trip planner uses a vehicles range to calculate the best route to a destination and automatically adds the closest and fastest charging points en route when the trip requires recharging. In each case, the driver sees an estimated time of arrival (ETA) and estimated charging time (ECT). The app adjusts the ETA based on any detours the driver takes, plus uses topological data to adjust the charging prediction. When the driver approaches the charging point, the car battery automatically starts heating up to improve the charging quality and reduce the charging time.

EV fleet monitoring

While electric vehicles require less maintenance, they arent completely maintenance-free. You have to monitor them for a number of health parameters, especially around battery use and depreciation. This requires a few things:

- Access to EV service specialists

- Timely procurement of spare parts

- An optimal EV fleet charging strategy

At present, automakers claim an average battery life of up to 500,000 miles (or around 800,000 kilometers). But battery degradation can happen earlier due to various environmental and usage factors. And that can result in a 3% to 5% annual range decrease.

Some OEMs are proposing swappable batteries as a solution. Replace the battery and youre good to go, they say. But scientists argue that swappable batteries paired with robotic servicing stations for fast swaps are neither economically nor technologically feasible.

Since batteries are so expensive, bulky, and resource-intensive, creating vast networks of swappable packswhich must be stored, kept charged, and maintainedwould be a waste of money and resources, while expanding carbon footprints. Many surplus batteries would end up sitting around, waiting for customers. Ultimately, customers would absorb these exorbitant costs.

So instead, we have to wait for wider availability of fast charging infrastructure and battery capacity improvements, which are already happening.

And while hardware innovation is happening, software can help you make the most out of available solutions.

Here are several software systems to facilitate EV fleet monitoring and performance optimization:

- Battery life prediction and analytics. E-vehicles come equipped with battery management systems (BMSs) that collect baseline performance data. This alone can be telling for your operations. However, you can also install extra sensors (pressure, temperature, etc.) to capture more data points. Then you can combine this data with fleet telematics to obtain a high-precision analysis of vehicle battery performance under different conditions. By adding machine learning algorithms, you can make such systems predictive (i.e. theyll provide you with estimates on battery capacity, depreciation over time, and servicing needs).

- Charging activity monitoring. EV charging stations come in three types Level 1, Level 2, and Level 3. Each offers a different charging speed and quality. When relying on public charging infrastructure, its good to know how effectively your assets will get charged. A remote charge monitoring solution can provide you with real-time consolidated or vehicle-specific information on charging status, speed, and cost. Also, if theres a sudden issue with a vehicles charging, the system can notify the driver to come and verify the problem so they dont arrive in the morning and face an uncharged vehicle.

- Asset tracking. Electric vehicles come with a greater degree of connectivity, and this quality can be used to implement more advanced electric vehicle tracking solutions. For example, you can provide more accurate ETA data to customers and docking stations, flag vehicles leaving authorized geofences, and program better dispatch schedules based on real-time connectivity.

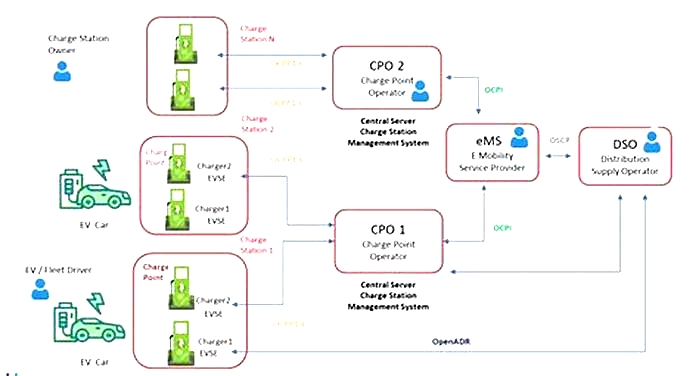

EV charging infrastructure management

While many smaller fleet management companies plan to use public charging infrastructure or private providers, bigger operators can gain more savings from building local charging infrastructure.

In fact, thats already in the works. DHL has partnered with Innogy, a German utility provider, to build EV charging infrastructure at 10 locations. DPD UK chose a commercial EV provider, Rolec, to supply them with EV chargers. In the US, a newly formed coalition of 53 investor-owned electric companies plans to build sufficient private and public infrastructure for local customers.

Going down the route of (co-)owning EV fleet charging infrastructure can lead to attractive cost savings if you can negotiate better tariffs with local energy providers. It also provides you with the ability to monitor your electric fleet with greater precision.

Here are several cost-saving EV charging infrastructure management features to consider:

- Fleet charging coordination. If you own a bevy of charging stations, you can centrally program an array of charging tasks such as scheduling vehicles that just finished a trip for charging, creating priority queues, plus collecting charging data on all vehicles to further optimize schedules.

- Intelligent EV charging management. Connected EV chargers, such as those with extra IoT sensors, can streamline the charging workflow. For example, you can automatically navigate drivers to a charging station, then authorize the vehicle using license plate reading technology or a connected cars digital ID. Once the vehicle is docked, the management module can suggest the optimal charging schedule based on the planned routes. For example, it can queue in-use cars for priority fast charging or delay charging for vehicles off rotation to benefit from off-peak energy tariffs.

- Remote charging station diagnostics. Connected charging stations hosted outside your premises will require servicing. While this chore will be shared with an infrastructure provider, you still need baseline data on charging station status (off/on/maintenance mode) to plan better routes. Similarly, if an EV fleet driver is facing unknown difficulties with charging, having the ability to remotely obtain and review the stations log messages can help them troubleshoot the problem.

To Conclude

Fleet electrification isnt a destination its a journey. Plan ahead for likely detours and necessary pit stops over the next five to ten years. When it comes to EV fleet management in particular, remember that the transition will require equal parts hardware and software investment. All new assets you purchase will have to be integrated into your operations.

And thats where you can truly gain an edge by leveraging built-in connectivity and new data streams from connected e-vehicles and charging infrastructure to enhance your route planning and execution capabilities!

Contact Intellias to discuss which supporting software solutions could help you run better electric fleet operations.