From Garage to Highway Building Your Own Electric Vehicle from Scratch

A Step-by-Step Guide on How to Build an Electric Car from Scratch: Empower Your Drive

Discover the fascinating world of electric vehicles by learning how to build your own electric car. This comprehensive guide provides a step-by-step approach to crafting your eco-friendly, custom electric vehicle.

Build An Electric Car: Unleashing Your DIY Potential

Embark on an exciting journey as we guide you through the process of building your very own electric car. From selecting components to fine-tuning performance, this guide will empower you to create a sustainable and efficient vehicle.

Read too: How to Become an Electric Car Mechanic and Shape the Automotive Revolution? Unleashing the Future

Understanding the Basics

The Fundamentals of Electric Vehicles

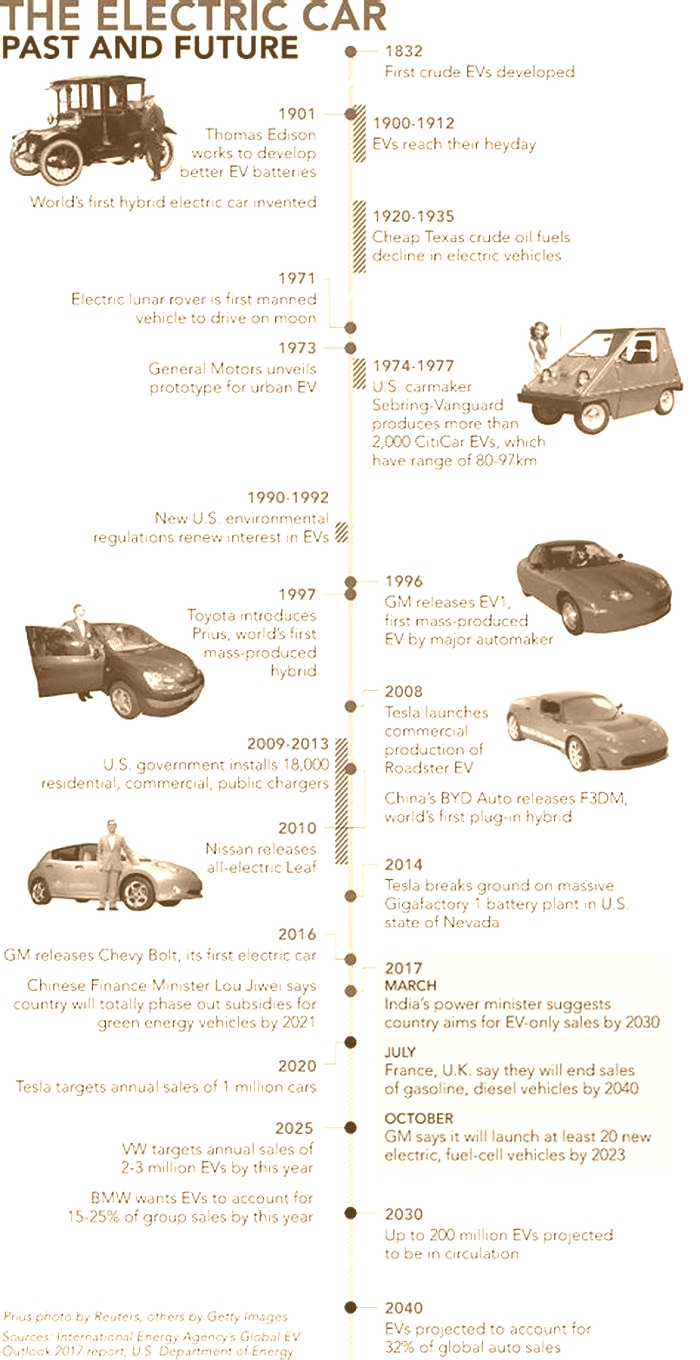

Dive into the fundamental principles of electric vehicles (EVs). Learn how electric cars work, understand the key components, and explore the environmental benefits of transitioning to an electric vehicle.

Planning Your Electric Car Project

Before diving into the build, effective planning is crucial. Explore the necessary considerations such as budgeting, design choices, and the essential components needed to make your electric car a reality.

Building Your Own Electric Car

Selecting the Right Components

Get acquainted with the essential components required for building an electric car. From batteries and motors to controllers and chargers, understand how each part contributes to the overall functionality of your DIY electric vehicle.

Crafting the Chassis and Body

Explore the process of designing and constructing the chassis and body of your electric car. Discover materials, aerodynamics, and safety considerations that are vital for creating a durable and visually appealing vehicle.

Wiring and Electronics

Delve into the intricacies of wiring and electronics. Learn how to connect batteries, controllers, and other electronic components to ensure seamless communication and optimal performance.

Performance Optimization

Enhancing Range and Efficiency

Explore techniques to enhance the range and efficiency of your DIY electric car. From aerodynamic improvements to battery management strategies, discover ways to maximize the performance of your custom-built vehicle.

Fine-Tuning the Motor and Controller

Understand the nuances of fine-tuning the motor and controller to achieve the desired balance between power and efficiency. Learn about programming and customization options to tailor your electric cars performance to your preferences.

Heading Towards the Future

Environmental Impact of DIY Electric Cars

Reflect on the positive environmental impact of DIY electric cars. Explore how building your own electric vehicle contributes to sustainability, reduces emissions, and fosters a sense of empowerment in eco-conscious transportation.

Conclusion Your Road to an Eco-Friendly DIY Electric Car

Sum up your electric car-building journey with a conclusion that encourages readers to embrace the challenge of creating their own electric vehicles. Highlight the sense of accomplishment and the positive impact on the environment.

Build Your Own Electric Car!

Currently, the car is insured and registered, although the DMV is still requiring that I drag it in and PROVE that there is no engine in the car before they give me the emissions tesing exemption.

This car can go for 20 miles on a charge, and has a top speed of 45 MPH, the speed limit right outside my house. In town is all 25 mph anyways. My typical ride is 10 miles for going to work, grocery store, post office, etc, and back home.

If I doubled up the battery pack, I should be able to go 30 to 40 miles on a charge.

This project has cost me about $1200 total, including buying the car in the first place. If I would have done the machining myself, I would have only spent around $800 for everything. This car charges at my house through a renewable energy program. All electricity comes from wind, bio-gas, and other renewable energy sources.

I kept the back seat and can carry four people total.

The original driver and passenger airbags are completely intact and functional.

I mostly drive this car in third gear. Turn the car on - put it in third - drive. It's really that easy. There's no engine to kill, so you don't have to push in the clutch before coming to a stop. The motor has so much torque that I can pull away from a dead stop in fourth gear.

I still need to come up with a heater.

(EDIT: Please see below)I think I will wear an extra thick coat and gloves for winter driving and have an electric defroster on the dashboard to keep it from frosting. The heat issue has been on my mind since the start of this project. The inefficiency of a gasoline engine is a blessing in a cold Wisconsin winter.

I did gloss over a few steps of this project.

I skipped telling you how many times I took apart, and put back together, the electric motor. How many times I lugged it back and forth to the machinist's. A friend and I were up til 2 in the morning one night fixing the control arm mount! Or how I had to literally shorten the motor because it was too long to fit in the car! But those things are for another story at another time!

I made sure to have an interlock, so I can't accidently drive away while plugged in. Make sure to have a nice big fuse inline of your main battery pack.

All the little challenges of a conversion like this are part of what makes it fun and interesting. In my case, I did a fair bit of experimenting of the best way to run the power brakes.

Winter Heat:Sure, gasoline engines aren't efficient, but all that waste heat sure is nice in the winter. Since this car no longer has the original engine, it doesn't have the original heat either. The blower motor is still there and works fine for defogging the windshield.

Some EV converters remove the original heater core and replace it with a ceramic heating element that runs on their pack voltage. That sounded like a lot of work, and I was already sick of tearing apart the dashboard.

I already had a household (120V AC) electric oil-filled radiator.I just put that behind the passenger seat, and run an extension cord out the window to a timer.

The heat comes on automatically in the morning and heats up the inside of the entire car before I get in it.

The mass of the oil in the radiator stays hot for about 10 minutes or so after I leave. Most of my trips aren't any longer than that anyways.

I like that with this heat system in that:

1) I didn't have to buy a darn thing

2) The entire interior of the car is already warm - seats, steering wheel, everything!

3) This also helps keep the batteries warm.

4) All the electric power comes from the wall, instead of the batteries

The only down side is that if I am parked all day somewhere that I can't plug in, I don't have that same heat for the ride home. On the other hand, most of my trips are pretty short, so it's not the end of the world.

This heat system consumes about 5 cents worth of electricity per use.

BRAKES:One of the reasons why I chose this car to convert was that it has manual windows, manual locks, manual transmission, non-powered steering,pretty much manual everything - except the brakes. The first time I drove the car as an electric conversion, I found the brakes to be a little hard. (You CAN stop the car WITHOUT power brakes, you just have to push really hard!) It was just a low-speed test drive, but it was pretty obvious that I had to work on the brake system. Power brakes work on vacuum created by the engine. Without an engine to make the vacuum, the brakes just don't work the way they should.

Some people say to find a different, manual, master brake cylinder and install that, or even just to punch a hole in a certain spot in the cylinder to convert it to manual. Neither of these sounded like great options. Really, I just needed an electric way to make a vacuum.

So, to start out with, I

played around with an aquarium air pump, just to learn how the vacuum brake system works. After that, I starting looking around for a 12v air pump with a connection on the "In" end, so that it could be used as a vacuum pump. A friend of mine dug one up, along with an aluminum bottle that had a threaded connector already on it.

I connected the air pump to 12V+ power through a vacuum switch. The vacuum switch measures vacuum in the bottle - if there isn't enough vacuum, the switch turns on the pump.

Now the car has power brakes, just like it did originally, only it's driven by a tiny electric motor in a little pump, instead of by a gasoline engine. Compare this to newer versions of the Prius, where the air conditioning is driven by an electric motor. That way, you can have AC without the engine running!

How-To Geek

As we all know by now, electric vehicles are expensive. And if you want to get a classic car converted into an EV, it'll cost you even more. As a result, we're seeing more people convert old gas-powered vehicles to EVs themselves.

If you want to build your own electric vehicle or watch others create amazing EVs in their garage, we have you covered.DIY electric vehicle builds can be rather dangerous, plus it's certainly not cheap, but it's a growing trend with impressive results. And while you can find countless beautiful EV conversions online, we wanted to highlight a few epic DIY electric vehicles.

All-Electric Military Humvee

Zack Nelson, the man behind the hugely popular JerryRigEverything YouTube channel, has spent the last year slowly building his electric truck. It's not just any truck, either. It's an original 1995 Military Humvee (HMMWV) with a cutout in the roof for guns and everything.

His channel is known for durability-testing smartphones and gadgets, but Zack has a slew of hobbies, including his new EV Humvee. Considering the GM Hummer EV is over $115,000, and the Cybertruck has seen several delays, he took matters into his own hands and made his own.

His videos are unique because they're informational, rather than just showing off cool stuff like most YouTubers. Zack shares the ups, downs, struggles, and failures, talks about why he went with Tesla battery cells, and details each decision along the way.

And yes, he removed the rear seats and tossed in a slew of Tesla battery cells to give this thing insane amounts of power and range. It's a fun one you don't want to miss.

You can watch the complete build series playlist here.

1978 Ferrari 308 GTS EV

The DIY Humvee above can go just about anywhere, but it's certainly not fast. If you have the need for speed, you'll love this 1978 Ferarri 308 GTS that ditched the powerful engine for battery packs and electric motors.

Two enthusiasts set out to make an old classic Ferrari faster than ever possible back in 1978 by turning it into an EV. The owners, Eric Hutchinson, and Brock Winberg, were so successful in making the first electric Ferrari that the entire DIY build ended up on the news with CNBC.

Related: How Long Does It Take to Charge an EV?

What makes this DIY EV Ferrari special is that it's still a supercar. It's faster than the original 308 GTS. And while I'm sure a few classic car owners will hate the idea of turning a classic into an EV and losing that sweet V8 sound, it's still pretty impressive to see what the two accomplished back in 2016.

Electric vehicles have come a long way over the last few years, but in 2016, things weren't quite as clear, making this DIY build one for the books. Now, they even sell kits so you can make your own DIY EV if you dare. Head to the ElectricGT website and see for yourself.

DIY Electric SuperCar

While several companies offer EV conversion kits, there's something special about watching a regular guy build one himself, with no help, in the comfort of his garage. The YouTube channel Electric SuperCar did exactly that, starting back in 2019, and the journey is one worth watching.

Related: 8 Amazing Rivian R1T Electric Truck Features

The creator took a K1-Attack kit car and slowly, piece by piece, transformed it into a stunning electric supercar unlike anything else on the road. Without an entire company, engineers, battery experts, R&D, and everything else Ford or Rivian has, this was a slow process. But as you can see, it was worth it.

Luckily for you, the video above is an entire overview of the DIY electric supercar. It talks about the steering and suspension, wiring the 12V systems, fabricating all the parts, tossing in Tesla motors, and everything else you'll want to know.

Ford Model A EV Conversion

Rich Benoit is a YouTuber with a channel known as Rich Rebuilds.And while he's made headlines for converting a Tesla into a V8-powered gas-guzzler that he takes to car shows, that's not the only project on the channel. In fact, Rich converted an old classic Ford Model A truck into a one-of-a-kind electric vehicle.

A DIY EV project is hard enough, but things get even more challenging when it's a vehicle as old as a Model A. He ripped out the powerful (for its time) Chevy 305 inside, tossed in some electric motors and battery packs, and fabricated several parts to make it all work.

His video covers some ugly truths about building your own EV and just how expensive the process can be. At first, his goal was to keep it affordable with Tesla parts, which proved challenging. The video explains how everything will end up more expensive than you probably budget for, but you'll still get to watch much of his process as he converts a classic rod into a modern EV.

Build Your Own EV

If any of these stories are giving you inspiration, you have several options these days. Popular websites like the DIYelectriccar forumare full of helpful tips, advice, and inspiration. Better yet, Ford jumped on the DIY train as fast as possible andsells the e-crate motor from its Mustang Mach-E. That way, regular folks can build the EV of their dreams.

Related: The Electric Truck Problem No One Is Talking About

You can get your own FordEluminator e-create engine for $4,300, and you'll be well on your way to building an electric vehicle. Then, Ford plans to offer more EV parts soon to help enthusiasts and DIYers bring their projects to life.

In the meantime, you'll probably have to fabricate a few parts, piece together some Tesla battery packs, and scour the internet until you find a solution that works for your build.

Or, you can watch from afar like I am and enjoy what others create.