How to Increase Your Electric Vehicle s Acceleration Without Sacrificing Range

Every watt counts: How Schaeffler is increasing the range of electric vehicles

2023-08-28 | Bhl

- Technical innovations by Schaeffler can increase the range of electric vehicles or enable comfort features to be used without sacrificing range.

- High-efficiency wheel and transmission bearings lower friction, significantly reducing losses.

- Intelligent, highly integrated thermal management components and systems boost EV range by up to 50 kilometers.

Worldwide, there are more and more electric cars on the road. In Germany, one in five new cars with battery-electric drive was sold in July 2023. However, range of electric vehicles is a commonly cited issue, with every second EV/hybrid driver in Europe reporting it as one of the top three concerns they have with their vehicles (source: Shell EV-Driver-Report 2023). On top of that, the motor isnt the only thing drawing on the battery. Especially in winter, all those creature comforts also use electricity at the expense of range. Schaeffler is doing a lot of work in this space, as CEO Automotive Technologies Matthias Zink explains: Schaeffler is developing solutions to combat range anxiety. Our smart technical solutions and wide range of components and systems for fully electrified powertrains improve the day-to-day practicality of electric vehicles by reducing power consumption and increasing range. Drivers thus have to charge their cars less frequently. Depending on the design of the vehicle application, vehicle manufacturers can also use the energy savings to make the battery smaller and thus the vehicle more cost-effective.

High-efficiency bearing solutionsAll cars need bearings and electric cars are no exception. That being so, one of the key ways of boosting range in electric cars is to reduce frictional losses where energy that would otherwise be used for powering the vehicle is lost as heat through bearing friction. Schaeffler has developed solutions to counter this. A set of highly efficient transmission bearings by Schaeffler can reduce friction significantly, saving about 50 watts of energy compared to conventional bearing solutions. That translates directly into extra range. Alternatively, in winter, those extra 50 watts can be put towards heating the exterior mirrors or steering wheel*, without any loss of range. Just as importantly, Schaefflers EV transmission bearings are specially adapted for the high rotational speeds of electric-drive transmission input shafts and therefore ensure optimal load accommodation.

For even more range, Schaeffler offers TriFinity wheel bearings. Wheel bearings are part of the electric vehicles chassis. They guide and support the drive shafts and axles, ensuring that the wheels can turn with minimal resistance, even under high mechanical load. Wheel bearings are subjected to immense forces during normal driving operation. And they are constantly in motion, rotating about 100 million times every 180,000 kilometers traveled. TriFinity wheel bearings by Schaeffler reduce frictional losses by a massive 67 percent compared to conventional bearings. That represents a saving of more than 200 watts, equating to about 20 kilometers of additional range in a fully charged electric SUV with a 120-kWh battery capacity. Alternatively, in winter, those extra 200 watts can be used for heating the driver and passenger seats* with no loss of range. Seat heating systems consume around 100 watts per seat during the intensive heating phase, whereas the TriFinity wheel bearing actually delivers its savings permanently. Furthermore, the triple-row TriFinity wheel bearing offers a weight saving of about 10 percent over standard double-row ball bearings for the same dimensions. It also offers a longer service life. As well as that, it boasts more than 20 percent greater stiffness, so it can transfer greater axle loads, which is a key advantage, especially in heavier electric vehicles.

Overcoming range anxiety with thermal managementThermal management offers major potential for range improvement and its an area in which Schaeffler has been developing solutions for around 15 years. Since 2011 Schaeffler has been supplying thermal management solutions to OEMs. Especially in electric vehicles, thermal management has a decisive influence on many customer-relevant features, such as range and comfort, and is therefore increasingly becoming a key competitive factor for automotive manufacturers, said Dr. Jochen Schrder, Head of the E-Mobility division at Schaeffler. Schaeffler is developing an array of solutions for this, ranging from versatile, multi-application components to highly integrated thermal management systems, to 4in1 e-axles that combine motor, transmission, power electronics and thermal management in a single, optimized unit. The 4in1 e-axle eliminates the additional hoses and cables required by decentralized thermal management systems, so less energy is lost. And because it has fewer parts, it weighs less and is easier for vehicle manufacturers to install. This fully integrated solution also yields further increases in range and charging speed because it keeps the powertrain, including the battery, at the right temperature. It keeps the vehicles occupants comfortable and at the right temperature as well. Thanks purely to the optimized interplay between its four subsystems, the 4in1 e-axle can save a compact electric car with a 75-kWh battery about 1 kWh of power per 100 kilometers of travel. Thats approximately seven percent more range, or about 36 kilometers.

Schaeffler is also developing a new type of heat pump for use both in the 4in1 e-axle and as a stand-alone component. The heat pump turns thermal energy from the surrounding air and waste heat from the motor, power electronics and battery into usable heating. This conserves battery power, which is at a premium in the colder winter months. Compared to a compact car with a 75-kWh battery and decentralized thermal management, the same vehicle with a 4in1 e-axle and heat pump system will use around 4 kWh less energy per 100 kilometers (measured in WLTC, based on an outside temperature of -7C). That equates to a 17 percent increase in range, or a gain of 48 kilometers. Alternatively, that saving can be put into added comfort and safety in the form of heated seats and steering wheel, heated exterior mirrors, and a heated rear windscreen (which together use about 410 watts of power*). Another advantage of the Schaeffler heat pump system is that it uses the naturally occurring refrigerant carbon dioxide (R744), which is much less harmful to the environment than the conventional refrigerant (Rf1234yf). R744 is non-combustible, has a low greenhouse gas potential, and does not damage the ozone layer. For automakers and car owners, this represents an investment in climate protection and the future.

* Power consumption reference values for vehicle functions (Source: ADAC)

Visit Schaeffler at the 2023 IAA Mobility show in Munich: At this years IAA Mobility show at the Munich Exhibition Center, Schaeffler is exhibiting a whole range of new technologies for sustainable, efficient and comfortable mobility. These include solutions for inner-city goods delivery using e-cargo bikes, a new type of steering system, high-efficiency electric and hydrogen drives, new mobility concepts, and more.

Schaeffler press conference: Monday, September 4, 2023, 11:00 a.m. to 11:20 a.m. (CEST): Klaus Rosenfeld, CEO of Schaeffler AG, and Matthias Zink, CEO Automotive Technologies at Schaeffler AG, will address the media at the Schaeffler showcase at Booth B40 in Hall B3 and online via live stream.

Schaeffler at the IAA Conference:

- Wednesday, September 6, 2023, from 4:00 p.m. to 4:45 p.m., Main Stage, Hall A1. Session: Towards a Sustainable Automotive Value Chain Ambitions, Challenges & Collaboration. Speakers include Matthias Zink, CEO Automotive Technologies, Schaeffler AG.

- Thursday, September 7, 2023, from 3:00 p.m. to 3:45 p.m., Visionary Clubhouse, Hall A2. Session: Here to innovate: revolution needs cooperation! Disruptive thinking, new technologies, new vehicle concepts partnerships as enablers for innovation and change. Speakers include Ralf Busse, mocci | CIP MOBILITY GmbH; Kersten Heineke, McKinsey Center for Future Mobility; Dennis Mller, Enchilada Franchise AG; and Claus-Dieter Schilling, Schaeffler.

Schaeffler and mocci are also teaming up for the IAA Experience at the IAA Summit in Hall A3. There, on the Cycling & Micromobility Course, visitors will be able to test-ride mocci e-cargo bikes featuring drive technology by Schaeffler. The IAA Experience is open from 9:00 a.m. to 6:00 p.m. daily from September 4 to 8.

5 ways to boost your range when driving electric

Range is such a hot topic in the world of EVs. And if youve got an EV, youre probably wondering what you can do to increase your range.

Well, grab your driving gloves, because were about to kick things into high gear, with five ways to boost your range:

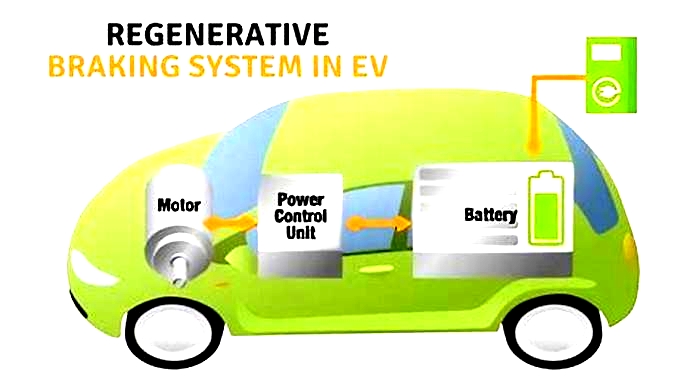

1. Use regenerative braking (if available)

Most EVs now have regen braking systems which act as a generator. So, as you break itll catch the energy that would otherwise be lost as heat, store it in the battery, and then give you a boost in range.

The amount of energy generated depends on the type of system installed, but typically it can add a few miles to a long journey.

To make the most out of regen braking, drive smoothly with mostly the accelerator and avoid any sudden braking.

2. Switch off any unnecessary features

Your EV battery doesnt just power the engine, it also powers all the gadgets and gizmos - from your headlights to your air-con. When youre trying to conserve battery power, switch off any features you dont need (yes, that means those heated seats once youve got a warm tooshie).

3. Keep your tyres inflated

Make sure your tyre pressure is as close to the recommended pressure (this can often be found on the inside of your passenger door or in your vehicle handbook) as possible. When your tyres are low on air, your car has to work extra hard to move because of increased rolling resistance. Its kind of like trying to walk on the sand instead of on the pavement.

So, by making sure your tyres are pumped up, youre not only going to glide more effortlessly down the road, but youll also be extending the amount of road you can glide down.

4. Take it steady on the pedal

If you put the pedal to the metal like youre flying down a race track, your EV would chug through energy faster than a toddler with a juice carton. And those dramatic braking moves - youre not just sending yourself flying forward, youre literally throwing energy out the window.

So, instead, take it easy on the pedals, and let your battery thank you with extra range.

5. Be smart with your charging

Like binge-watching shows, binging on charging isnt always the best idea. The best way to keep your EVs battery in good condition and boost range is to charge regularly and keep it topped up between 20 - 80%.

So, what can you do to boost your EVs range?

Check your tyre pressure, be gentle with the pedals, let that regen work its magic, and maybe, just maybe, think about turning off that heated steering wheel. You'll be travelling from lands end to John ogroats in no time (topping up to 80% along the way of course).Want to find out more about EVs? Take a look at our EV Hub.

Noise Emission Models of Electric Vehicles Considering Speed, Acceleration, and Motion State

Int J Environ Res Public Health. 2023 Feb; 20(4): 3531.

Noise Emission Models of Electric Vehicles Considering Speed, Acceleration, and Motion State

, Methodology, Software, Validation, Formal analysis, Investigation, Data curation, Writing original draft, Writing review & editing, Visualization,1,2,3 , Writing review & editing, Supervision,1,2 , Writing review & editing, Supervision,1,2 and , Writing review & editing, Supervision, Project administration, Funding acquisition3,*

Ziqin Lan

1National Environmental Protection Engineering and Technology Center for Road Traffic Noise Control, Beijing 100088, China

2Research Institute of Highway Ministry of Transport, Beijing 100088, China

3School of Automobile and Transportation Engineering, Guangdong Polytechnic Normal University, Guangzhou 510665, China

Minmin Yuan

1National Environmental Protection Engineering and Technology Center for Road Traffic Noise Control, Beijing 100088, China

2Research Institute of Highway Ministry of Transport, Beijing 100088, China

Shegang Shao

1National Environmental Protection Engineering and Technology Center for Road Traffic Noise Control, Beijing 100088, China

2Research Institute of Highway Ministry of Transport, Beijing 100088, China

Feng Li

3School of Automobile and Transportation Engineering, Guangdong Polytechnic Normal University, Guangzhou 510665, China

Lingxin Chen, Academic Editor

1National Environmental Protection Engineering and Technology Center for Road Traffic Noise Control, Beijing 100088, China

2Research Institute of Highway Ministry of Transport, Beijing 100088, China

3School of Automobile and Transportation Engineering, Guangdong Polytechnic Normal University, Guangzhou 510665, China

Received 2023 Jan 31; Revised 2023 Feb 12; Accepted 2023 Feb 13.

- Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Abstract

Electric vehicles, known for their low-noise emission, are popular and widespread in metropolises in China, and they provide an opportunity for a reduction in environmental noise from vehicles. To understand the noise from electric vehicles better, this study develops noise emission models considering speed, acceleration, and motion state. The model construction is based on the data collected from a pass-by noise measurement experiment in Guangzhou, China. The models describe a linear relationship between the noise level, the logarithm of speed, and the acceleration for multiple motion states (i.e., the constant-speed state, the acceleration state, and the deceleration state). From the spectrum analysis, the low-frequency noise is barely affected by the speed and acceleration, but the noise at a certain frequency is most sensitive to them. Compared to other models, the proposed ones have the highest accuracy and the greatest ability for extrapolation and generalization.

Keywords: road traffic noise, electric vehicle, noise emission model, acceleration, motion state

1. Introduction

Road traffic noise becomes the main source of environmental noise in large cities due to the densification of road networks and the growing number of vehicles. It has negative impacts on residents health, such as cardiovascular diseases, hypertension, cognitive impairments, high sleep disturbance, and annoyance [1,2,3]. The health impacts of road traffic noise raise concern among the policymakers and the general public in China. Since 5 June 2022, the new law on the prevention and control of noise pollution has been put into force by the Chinese government. The law declares that the state must promote the system of standards for the prevention and control of noise pollution. Noise emission models are the foundation of the tools for understanding and reducing traffic noise pollution [4,5,6,7], e.g., dynamic traffic noise simulation [8,9] and traffic noise mapping [10,11,12]. Nowadays, electric vehicles (e.g., electric cars and electric buses) occupy a quite large proportion of vehicles in metropolises on account of incentive policies and the advantage of low-carbon emissions [13] and low-noise emissions [14] in contrast to internal combustion engine vehicles. The characteristics of road traffic noise in metropolises have enormous changes because of the intervention of the increasing number of electric vehicles.

However, the standards, regulations, and guidelines about the noise emission of vehicles have not yet been updated, and some contents do not meet the requirements of assessing road traffic noise in the current environment. The recommended noise emission models in these official documents still maintain the original version, which was derived from the data collected from internal combustion engine vehicles. Thus, to describe the characteristics of noise emission in the new situation and update the relevant content of the traffic noise standards, this study aims to develop noise emission models of electric vehicles by a pass-by noise measurement. The proposed models take into account the speed of vehicles, similar to the existing emission models (e.g., the CoRTN model [15], the RLS 90 model [16], the NMPB model [17,18], the Harmonoise model [19,20], the ASJ-RTN model [21,22]), as well as the acceleration and the motion state of electric vehicles. The contribution of this study is the noise emission models of electric vehicles considering speed, acceleration, and motion state for the traffic noise environment of China.

The rest of the paper is organized as follows. Section 2 reviews the related works of the traffic noise prediction model. Section 3 describes the details of the measurement experiment and the collected data. Section 4 constructs the noise emission models of electric vehicles and conducts some relevant analyses. Section 5 compares the proposed model with other models and tests the performance. Section 6 concludes the paper.

2. Literature Review

There are many studies on noise emission models of traditional vehicles. These studies can provide a basic modeling idea for electric vehicle noise emission. We summarize the common noise prediction models, e.g., the CoRTN model, the RLS 90 model, the NMPB model, the Harmonoise noise prediction model, the CNOSSOS-EU model, the FHWA model, and the ASJ-RTN model below:

(1)

The CoRTN model (i.e., calculation of road traffic noise model) [

15] is based on traffic flow through a road segment in an hour, and it also takes into account traffic speed, heavy vehicle percentage, road gradient, pavement type, distance, shielding, angle of view, and reflection.

(2)

The RLS 90 model (i.e., Richtlinien fr den Lrmschutzan a Strassen-90) [

16] is a function of the speed limit of roads considering vehicle type, including an additional correction accounting for the increased effect of traffic lights at intersections.

(3)

The NMPB model (i.e., the French method for road traffic noise prediction) [

17,

18] consists of a rolling noise component and a power unit noise component, and it takes into consideration traffic flow conditions (i.e., the steady traffic flow and the unsteady traffic flow) and road surface aging.

(4)

The Harmonoise noise prediction model [

19,

20], developed in the European projects Harmonoise and Imagine, decomposes the noise emission of a vehicle as the energetic sum of a rolling noise and a propulsion noise, which are both related to the speed of vehicles, and it takes account of the acceleration by using a correction.

(5)

The CNOSSOS-EU model (i.e., European-common noise assessment methods) [

23] includes two parts: a rolling noise and a propulsion noise, which are both correlated to the traffic speed, but it ignores the effect of acceleration and deceleration because it is developed for generating strategic noise maps.

(6)

The FHWA model (i.e., federal highway administrative model) [

24,

25] is expressed as a function of vehicle speed, and it uses a term to reflect the traffic flow regime, but it does not represent the acceleration of vehicles explicitly.

(7)

The ASJ-RTN model (i.e., Acoustical Society of Japan-Road Traffic Noise model) [

21,

22] describes a linear relationship between the noise level and the logarithm of speed, including some correction terms for road-related factors. It also considers the effect of the traffic flow states (i.e., the steady state and the unsteady state).

Additionally, many scholars improve the above models to achieve better accuracy for traffic noise prediction in some specific situations. Can and Aumond [26] analyzed the sensitivity of estimated road traffic emissions to vehicle kinematics variables and improved the noise emission models through the introduction of additional traffic parameters. Asensio et al. [10] presented a method of calculating the contribution of a specific vehicle to the overall noise pollution, which depended on the type and state of maintenance of the vehicle and road surface, the speed of the vehicle, the acceleration, and the type of driving. Pascale et al. [27] modeled vehicle noise emission considering the impact of kinematic variables. Peng et al. [28,29] developed a six-category heavy vehicle source emission model in free-flowing conditions based on the statewide road setting in New South Wales, Australia. Snchez-Fernndez et al. [30] studied the influence of temperature on the sound pressure level of tireroad noise emissions under actual conditions of continuous vehicle flow. Cai et al. [31] developed a traffic noise emission model on a wet asphalt road based on traffic noise measurements. Abdur-Rouf et al., [32], Gardziejczyk et al., [33], Khajehvand et al., [34], and Yadav et al. [35] developed traffic noise prediction models for urban intersections. These above models both consider traffic speed and traffic flow as main variables and introduce some correction terms that account for the road-related factors and the environmental factors. They belong to linear models, i.e., larger traffic speed and larger traffic flow lead to a higher noise emission level, and they are usually expressed as explicit functions of the vehicle-related factors and road-related factors and are always constructed by using the data collected from statistical pass-by measurement experiments.

By contrast, some studies use machine learning methods to present the nonlinear relationship between noise emission and its factors [36,37,38]. Whether linear models or machine learning models, they are static models that are suitable for calculating the noise level over a period, but they cannot simulate the dynamic changes in noise emission. To this end, dynamic simulation methods of traffic noise based on microscopic traffic simulation are proposed [8,39,40,41].

However, the above models both account for internal combustion engine vehicles instead of electric vehicles. To our knowledge, the study of noise models of electric vehicles is not as comprehensive as that of internal combustion engine vehicles. Pallas et al. [42] proposed a noise emission model for extending CNOSSOS-EU to light electric vehicles. Lan et al. [14] developed noise emission models for electric cars and electric buses but only took into account vehicle speed. Cesbron et al. [43] studied the potential influence of the road surface on the noise emission of electric vehicles in urban areas by a pass-by noise measurement. Pallas et al. [44] investigated the noise emission of electric trucks at a constant speed and modeled the power unit noise as a function of the engine or motor speed and the rolling noise as a function of the vehicle speed. Czuka et al. [45] compared nine different sets of tires by carrying out pass-by measurements for the modeling of rolling noise from electric vehicles. These models only take into consideration the impact of vehicle speed on the noise emission of electric vehicles.

In addition to the speed, the acceleration and the motion state also affect the noise emission of electric vehicles. For example, the noise emission of a vehicle in an acceleration state is different from that in a deceleration state, even if the absolute values of the accelerations are the same. Therefore, based on intuitive recognition, this study also takes into consideration the impacts of acceleration and motion state on the noise emission of electric vehicles to provide a better description and improve the estimation accuracy of noise emission.

3. Experiment and Data

A field experiment was performed to measure and model the noise emission of electric vehicles and collect pass-by noise levels and motion parameters (i.e., speed and acceleration). The experiment was conducted at Waihuanxi Road, a six-lane road in the Higher Education Mega Center, Guangzhou, China. The experimental situation consists of the flat and dry drainage asphalt pavement, the 2130 C air temperature, and the clear surroundings without obstruction. In general, there were few social vehicles running on the road, especially in the morning. The background noise was measured five times, and these sound pressure levels are 43.2, 41.0, 41.5, 42.9, and 42.5 dB(A), respectively. Thus, the effects of non-experimental vehicle noises and background noises were rather negligible.

The measurement method refers to the Limits and Measurement Methods for Noise Emitted by Accelerating Motor Vehicles (GB 1495-2002), Chinas official manual of vehicle noise measurement. Before the experiment, a sound level meter (HzAiHua AWA6228+) was calibrated by a calibrator and placed on a side of the measurement road. The microphone of the sound level meter is positioned at 1.2 m above the road surface and 7.5 m away from the center line of the first lane. Two radar speedometers were placed on both sides of the sound level meter symmetrically, and they were ten meters apart. These three instruments were both at the same horizontal plane. The layout of the instruments in the measurement area is shown in .

Layout of the instruments.

Four electric cars were used in the experiment. They are a kind of sedan produced by Beijing Electric Vehicle Co., Ltd. (Beijing, China), and their models are both BAIC BJEV160. The main parameter configuration of the electric cars is shown in . It is noted that the noise emission of vehicles is dependent on the size and type of electric vehicles, but the following proposed noise emission models based on this experiment are still applicable to electric cars with a similar parameter configuration.

Table 1

The parameter configuration of the experimental electric cars.

| Configuration | Description |

|---|---|

| Power type | Pure electric vehicle |

| Body structure | Hatchback sedan |

| Engine | 45 kW electromotor |

| Maximum power of motor (kW) | 45 |

| Maximum torque of motor (Nm) | 144 |

| Energy capacity of battery (kWh) | 25.6 |

| Size (mm) | 4025 1720 1503 |

| Wheelbase (mm) | 2500 |

| Weight (kg) | 1295 |

| Maximum speed (km/h) | 125 |

During the experiment, skilled drivers drove the electric cars one by one through the measurement area in different driving states (i.e., at a constant speed, an accelerated speed, or a decelerated speed). When the car entered and exited the measurement area steadily (i.e., traveled at a constant speed or at a steady acceleration/deceleration), the speed values were recorded by the radar speedometers. These speed values were used to estimate the acceleration of the car. According to the study [46], the acceleration is calculated by Equation (1):

where is the distance between the two radar speedometers, i.e., 20 m; and are the speed values when the car entered and exited the measurement area, respectively. It should be noted that the acceleration was assumed to be constant when the car passed through the measurement area.

When the car passed by the sound level meter, the A-weighted noise level, and the 1/3 octave band spectrum (from 12.5 Hz to 16 kHz) were collected by the sound level meter, and the instantaneous speed was recorded manually through the car dashboard. In brief, a triple consisting of a noise level, a speed value, and an acceleration value can be obtained after each pass-by measurement.

After the experiment, there are 330 valid triples in total. A total of 117 of them corresponds to the constant-speed state, 101 of them correspond to the deceleration state, and 112 of them correspond to the acceleration state. In this dataset, the range of the noise level is from 51.65 dB(A) to 69.17 dB(A); the speed range is from 24 km/h to 62 km/h, which is in a legal vehicle speed range of urban roads; the acceleration range is from 2.19 m/s2 to 2.06 m/s2. The detailed statistical result of the grouped data is shown in .

Table 2

Statistical result of the data grouped by motion state and speed range.

| Motion State | Range ofSpeed (km/h) | Record Number | Range ofAcceleration (m/s2) | Range ofNoise Level (dB(A)) |

|---|---|---|---|---|

| Constant-speed state | 6 | 0 | [53.21, 58.88] | |

| [30.0, 40.0) | 41 | 0 | [52.72, 62.79] | |

| [40.0, 50.0) | 55 | 0 | [56.50, 66.60] | |

| 15 | 0 | [60.01, 68.71] | ||

| Acceleration state | 14 | [0.72, 1.94] | [55.11, 60.21] | |

| [30.0, 40.0) | 57 | [0.48, 1.59] | [51.65, 68.39] | |

| [40.0, 50.0) | 35 | [0.52, 2.06] | [58.92, 67.41] | |

| 6 | [1.32, 2.06] | [62.73, 68.81] | ||

| Deceleration state | 13 | [1.63, 0.69] | [55.60, 60.26] | |

| [30.0, 40.0) | 47 | [1.90, 0.56] | [55.99, 66.23] | |

| [40.0, 50.0) | 32 | [2.19, 0.59] | [61.46, 68.95] | |

| 9 | [2.19, 0.56] | [61.92, 69.17] | ||

| Total | 330 |

For a preliminary understanding of the collected data, we used the 1/3 octave band spectra to calculate the noise energy percentage based on the groups mentioned in . According to the studies [14,46], the noise energy percentage is described as

where is the A-weighted sound pressure level corresponding to the i-th center frequency in the 1/3 octave band spectrum; is the noise energy corresponding to ; is the noise energy percentage corresponding to the i-th center frequency.

shows the noise energy percentages of the groups based on the motion state and the speed range. Overall, the noise energy is concentrated in the frequency range between 500 Hz and 1600 Hz, and the peak is located at the frequency of 1000 Hz for each group mainly. These are consistent with the results of the work [14]. For each motion state, the noise energy distributes in a wider domain in the low-speed range. As the speed increases, the noise energy converges on a high-frequency range gradually. This indicates that electric vehicles at low speeds are inclined to emit obvious low-frequency noise. At the same speed range, the noise energy of the constant-speed state is more concentrated at the frequency of 1000 Hz than that of the acceleration state or the deceleration state, while the noise energy of the acceleration state at the 500-Hz frequency is higher than those of the constant-speed state and the deceleration state. In contrast with the constant-speed state and the acceleration state, there is an apparent peak at the frequency of 6300 Hz in the deceleration state, which may be caused by the braking and the friction of tires against the road surface. To sum up, different motion states of electric vehicles lead to different noise emissions; thus, it is necessary to construct noise emission models for different states separately.

Noise energy percentages of the groups based on the motion state and the speed range (The color of a grid varies from green to red depending on the value of the grid, i.e., a green grid represents a small percentage value and a red grid represents a large percentage value).

4. Noise Emission Models of Electric Vehicles

4.1. Model Construction

In the previous studies [15,16,17,18,19,20,21,22], noise emission of traditional vehicles (i.e., internal combustion engine vehicles) was always expressed as a linear function of vehicle speed. In reality, the noise level of electric vehicles is related to the speed and acceleration of electric vehicles. Specifically, higher speed and higher acceleration lead to larger noise levels. Based on the phenomenon and the previous studies, a linear model is used to represent the relationship between the noise emission of electric vehicles and its relevant factors, i.e., speed and acceleration. The linear model is described as

where is the A-weighted sound pressure level; is the speed of an electric vehicle; is the acceleration of an electric vehicle; , , and are the coefficients determined by least squares methods.

Considering the impact of the motion state of electric vehicles on noise emission, which is mentioned in Section 3, three empirical models are fitted by the collected data for the three motion states, i.e., the constant-speed state, the acceleration state, and the deceleration state. To calibrate the coefficients of the models, we divided the collected data into three parts according to the motion states and then divided each part into a training set and a validation set randomly. The training set consists of 90% of the records of the collected data, and the validation set consists of the remaining records. The proposed models were calibrated by using the training set to obtain the optimal parameters , , and . The final empirical models are as follows:

(6)

where is a positive value.

(7)

where is a negative value.

The coefficients of determination of the three models are 0.46, 0.54, and 0.67, respectively. Additionally, the t-test was used to test the linear significance of these models. The t-test values are both larger than the corresponding critical values, which indicates that there are linear relationships between the noise level of electric vehicles and its relevant factors and proves the rationality of these models.

4.2. Accuracy Analysis of the Models

The performance of the proposed models was tested by using the validation set. In the validation set, there are 11 records belonging to the constant-speed state, 11 records belonging to the acceleration state, and 10 records belonging to the deceleration state. The metric of accuracy is the root mean square error (), which is described as,

(8)

where is the n-th truth value; is the n-th estimated value; is the number of truth values or the estimated values.

The s corresponding to the constant-speed state, the acceleration state, and the deceleration state are 2.12 dB(A), 1.85 dB(A), and 2.10 dB(A), respectively. These RMSEs are both less than the reference accuracy value, i.e., 3 dB(A), which is suggested by the Good Practice Guide for Strategic Noise Mapping and the Production of Associated Data on Noise Exposure [47]. If the motion state is not taken into consideration, namely that the accuracy verification is conducted on the validation set regardless of the motion state, then the 2.16-dB(A) is greater than those corresponding to the three motion states. Therefore, the proposed models considering the motion states have a better performance for predicting the noise emission of electric vehicles.

4.3. Analysis of the Spectra and the Factors

To understand the impacts of the factors on the spectra, we fitted the linear model between the noise level and the factors for each center frequency. , and show the coefficients of determination, the fitting coefficients, and the s of the fitted linear models corresponding to the center frequencies and the motion states. According to the definition of the coefficient of determination, a larger value indicates a more significant linear relationship between the noise level and the factors.

Table 3

The coefficients of determination, the fitting coefficients, and the s of the fitted linear models corresponding to the constant-speed state at different center frequencies.

| CenterFrequency(Hz) | Coefficientof Determination | CenterFrequency(Hz) | Coefficientof Determination | ||

|---|---|---|---|---|---|

| 12.5 | 0.00 | 5.64 | 500 | 0.33 | 2.94 |

| 16 | 0.00 | 6.46 | 630 | 0.31 | 2.41 |

| 20 | 0.01 | 4.57 | 800 | 0.41 | 3.64 |

| 25 | 0.02 | 2.80 | 1000 | 0.31 | 3.20 |

| 31.5 | 0.02 | 2.11 | 1200 | 0.64 | 2.76 |

| 40 | 0.00 | 2.42 | 1600 | 0.70 | 2.21 |

| 50 | 0.01 | 3.89 | 2000 | 0.52 | 3.00 |

| 63 | 0.01 | 2.95 | 2500 | 0.32 | 3.57 |

| 80 | 0.01 | 1.47 | 3100 | 0.21 | 3.94 |

| 100 | 0.01 | 2.51 | 4000 | 0.22 | 3.29 |

| 125 | 0.03 | 1.86 | 5000 | 0.27 | 6.53 |

| 160 | 0.09 | 1.85 | 6300 | 0.16 | 10.12 |

| 200 | 0.10 | 2.55 | 8000 | 0.11 | 9.02 |

| 250 | 0.14 | 2.18 | 10,000 | 0.10 | 5.14 |

| 315 | 0.24 | 1.61 | 12,500 | 0.00 | 4.54 |

| 400 | 0.41 | 2.42 | 16,000 | 0.00 | 5.19 |

Table 4

The coefficients of determination, the fitting coefficients, and the s of the fitted linear models corresponding to the acceleration state at different center frequencies.

| Center Frequency (Hz) | Coefficient ofDetermination | CenterFrequency (Hz) | Coefficient ofDetermination | ||

|---|---|---|---|---|---|

| 12.5 | 0.02 | 4.97 | 500 | 0.23 | 1.60 |

| 16 | 0.02 | 4.71 | 630 | 0.28 | 2.23 |

| 20 | 0.04 | 4.50 | 800 | 0.37 | 2.82 |

| 25 | 0.04 | 2.92 | 1000 | 0.53 | 2.70 |

| 31.5 | 0.06 | 3.45 | 1200 | 0.62 | 3.23 |

| 40 | 0.00 | 3.02 | 1600 | 0.52 | 4.05 |

| 50 | 0.05 | 3.83 | 2000 | 0.45 | 2.84 |

| 63 | 0.05 | 4.97 | 2500 | 0.42 | 4.35 |

| 80 | 0.00 | 2.80 | 3100 | 0.37 | 3.80 |

| 100 | 0.04 | 2.46 | 4000 | 0.32 | 3.52 |

| 125 | 0.13 | 2.28 | 5000 | 0.20 | 3.49 |

| 160 | 0.17 | 1.69 | 6300 | 0.10 | 5.13 |

| 200 | 0.15 | 2.35 | 8000 | 0.11 | 3.98 |

| 250 | 0.09 | 2.28 | 10,000 | 0.05 | 1.71 |

| 315 | 0.14 | 1.49 | 12,500 | 0.13 | 2.79 |

| 400 | 0.37 | 2.01 | 16,000 | 0.12 | 2.65 |

Table 5

The coefficients of determination, the fitting coefficients, and the s of the fitted linear models corresponding to the deceleration state at different center frequencies.

| Center Frequency (Hz) | Coefficient ofDetermination | Center Frequency (Hz) | Coefficient ofDetermination | ||

|---|---|---|---|---|---|

| 12.5 | 0.04 | 5.86 | 500 | 0.82 | 1.36 |

| 16 | 0.01 | 5.03 | 630 | 0.73 | 1.97 |

| 20 | 0.02 | 4.65 | 800 | 0.71 | 1.86 |

| 25 | 0.04 | 4.13 | 1000 | 0.55 | 1.85 |

| 31.5 | 0.03 | 4.06 | 1200 | 0.43 | 1.95 |

| 40 | 0.03 | 3.76 | 1600 | 0.29 | 2.06 |

| 50 | 0.08 | 4.55 | 2000 | 0.32 | 2.13 |

| 63 | 0.07 | 3.53 | 2500 | 0.34 | 2.40 |

| 80 | 0.08 | 3.43 | 3100 | 0.31 | 2.11 |

| 100 | 0.05 | 2.02 | 4000 | 0.33 | 1.66 |

| 125 | 0.04 | 1.89 | 5000 | 0.08 | 8.27 |

| 160 | 0.26 | 1.71 | 6300 | 0.03 | 12.02 |

| 200 | 0.41 | 1.58 | 8000 | 0.09 | 10.07 |

| 250 | 0.48 | 1.77 | 10,000 | 0.15 | 6.73 |

| 315 | 0.60 | 1.64 | 12,500 | 0.10 | 3.64 |

| 400 | 0.71 | 2.11 | 16,000 | 0.13 | 3.12 |

In terms of the constant-speed state, the noise is insensitive to the change in vehicle speed in the frequency ranges from 12.5 Hz to 160 Hz and from 12,500 Hz to 16,000 Hz, while the noise is related significantly to the speed of electric vehicles in the frequency range from 400 Hz to 2500 Hz. The maximum coefficient of determination is at the frequency of 1600 Hz and its value is 0.70. The noise level increases with the vehicle speed.

In terms of the acceleration state, the noise is more related to the speed and the acceleration of electric vehicles in the frequency range from 400 Hz to 4000 Hz than in the frequency range from 12.5 Hz to 100 Hz. The maximum coefficient of determination is at the frequency of 1200 Hz, and its value is 0.62. There is a strong and positive relationship between the noise level, the speed, and the acceleration.

In terms of the deceleration state, the noise is not sensitive to the changes in the speed and acceleration of electric vehicles in the frequency range from 12.5 Hz to 125 Hz, while there are strong linear relationships between the noise level, the speed, and the acceleration in the frequency range from 200 Hz to 4000 Hz. The maximum coefficient of determination is at the frequency of 500 Hz, and its value is 0.82. A larger spend and a larger acceleration lead to a larger noise level.

As shown in , regardless of the motion states, the coefficients of determination corresponding to the frequency range from 400 Hz to 2500 Hz are greater than 0.3, which indicates that the noise is more related to the speed and the acceleration than in other ranges, but the maximum of the coefficient of determination is at the frequency of 800 Hz, and its value is 0.47. The maximum is smaller than that corresponding to the three motion states mentioned above. Therefore, it is necessary to build the noise emission models of electric vehicles based on the motion states.

Table 6

The coefficients of determination, the fitting coefficients, and the s of the fitted linear models at different center frequencies regardless of the motion states.

| CenterFrequency(Hz) | Coefficient ofDetermination | CenterFrequency(Hz) | Coefficient ofDetermination | ||

|---|---|---|---|---|---|

| 12.5 | 0.06 | 6.10 | 500 | 0.38 | 2.22 |

| 16 | 0.06 | 5.92 | 630 | 0.37 | 2.40 |

| 20 | 0.04 | 4.71 | 800 | 0.47 | 2.86 |

| 25 | 0.06 | 3.10 | 1000 | 0.43 | 2.71 |

| 31.5 | 0.01 | 3.15 | 1200 | 0.44 | 3.21 |

| 40 | 0.05 | 2.90 | 1600 | 0.36 | 3.63 |

| 50 | 0.09 | 3.92 | 2000 | 0.33 | 3.13 |

| 63 | 0.09 | 3.87 | 2500 | 0.30 | 3.90 |

| 80 | 0.01 | 2.43 | 3100 | 0.25 | 3.67 |

| 100 | 0.08 | 2.48 | 4000 | 0.25 | 3.14 |

| 125 | 0.08 | 2.12 | 5000 | 0.10 | 6.69 |

| 160 | 0.14 | 1.77 | 6300 | 0.04 | 9.92 |

| 200 | 0.15 | 2.40 | 8000 | 0.06 | 8.65 |

| 250 | 0.13 | 2.39 | 10,000 | 0.08 | 4.86 |

| 315 | 0.22 | 1.81 | 12,500 | 0.04 | 3.50 |

| 400 | 0.43 | 2.25 | 16,000 | 0.02 | 3.43 |

5. Discussion

5.1. Comparison with Other Models

During model construction, we assumed that there was a linear relationship between the noise emission, the speed, and the acceleration of an electric vehicle and used a linear model to fit the collected data. However, some studies use machine learning methods to express the potential nonlinear relationship between noise emission and its factors [36,37,38].

To determine what kind of model is suitable for describing the potential relationship, we compared the proposed models with the other five models on the validation set considering the speed, acceleration, and motion state of electric vehicles. Among the five models, one is a linear model, and the others are often used to capture the nonlinear relationships. The comparative models are as follows:

(1)

The first kind of model is a linear model, but it only takes the speed of the electric vehicle into account, i.e., . This kind of model was common in modeling noise emissions of internal combustion engine vehicles in previous studies. For convenience, this model is named LR_1para.

(2)

The second kind of model is a support vector regression model (SVR) [

48]. Support vector regression is a regression algorithm that supports both linear and nonlinear regressions. There are three preset parameters in the model: a regularization parameter C, an epsilon, and a kernel. In the comparison, the C is 1, the epsilon is 0.2, and the kernel is the radial basis function (RBF) kernel.

(3)

The third kind of model is a Gaussian process regression model (GPR) [

49]. Gaussian process regression also can capture the linear and nonlinear relationship of data. The type of kernel needs to be preset. In the comparison, the chosen kernel is the sum of a dot product kernel and a white kernel.

(4)

The fourth kind of model is a random forest model (RF) [

50]. A random forest is a meta-estimator that fits a number of classifying decision trees on various sub-samples of the dataset. In the comparison, the number of trees in the forest is 100.

(5)

The fifth kind of model is a multi-layer perceptron regressor (MPR) [

51], which is a kind of neural network. In the comparison, the network has a hidden layer with 100 neurons; the activation is the rectified linear unit function ReLu; the learning rate is 0.001; the strength of the L2 regularization term is 0.0001; the solver is Adam, a stochastic gradient-based optimizer.

We trained these models by the training set and calculated the by the validation set. For the sake of description, the proposed models are named LR_2para in the following. shows the coefficients of determination and the s of the six models on four validation sets. The coefficient of determination reflects the goodness of fit of the model and the represents the predictive ability of the model. Whether in the aspect of the goodness of fit or the predictive ability, the performance of the two linear models (i.e., LR_2para and LR_1para) is superior to that of the other four models (i.e., SVR, GPR, RF, and MPR). The LR_2para model is more suitable for representing the noise emission of electric vehicles than the LR_1para model. This proves that the hypothesis of the proposed models is correct.

Table 7

Comparative results of the six models on four validation sets.

| Model | LR_2para | LR_1para | SVR | GPR | RF | MPR | |

|---|---|---|---|---|---|---|---|

| Constant-speed state | Coefficient of determination | 0.46 | 0.46 | 0.18 | 0.05 | 0.63 | 0.44 |

| (dB(A)) | 2.12 | 2.12 | 4.04 | 4.07 | 4.52 | 4.36 | |

| Acceleration state | Coefficient of determination | 0.54 | 0.53 | 0.46 | 0.13 | 0.87 | 0.54 |

| (dB(A)) | 1.85 | 1.7 | 3.33 | 3.06 | 4.01 | 3.68 | |

| Deceleration state | Coefficient of determination | 0.67 | 0.57 | 0.08 | 0.08 | 0.95 | 0.65 |

| (dB(A)) | 2.1 | 2.36 | 3.16 | 3.04 | 4.66 | 3.59 | |

| Regardless of the motion states | Coefficient of determination | 0.5 | 0.47 | 0.29 | 0.21 | 0.81 | 0.49 |

| (dB(A)) | 2.16 | 2.26 | 3.16 | 3.53 | 4.52 | 3.92 |

5.2. Extrapolation Analysis of Different Models

Extrapolation is defined as an estimation of the value of a variable on the basis of its relationship with other variables beyond the original observation range. The ability of extrapolation reflects the generalization ability of models, i.e., the performance of predicting the noise level based on the unobserved values of the correlative factors. To validate the ability of extrapolation of the models, we derived two training sets and two validation sets from the collected data according to the speed range:

(1)

Situation 1: The validation set consists of the records whose speed values are less than 30 km/h, and the training set consists of the rest of the records.

(2)

Situation 2: The validation set consists of the records whose speed values are greater than 50 km/h, and the training set consists of the rest of the records.

The six models were trained by the training set and validated by the validation set for Situation 1 and Situation 2, respectively. shows the training errors and the prediction errors of the six models in Situation 1. shows the training errors and the prediction errors of the six models in Situation 2. With regard to Situation 1, the training error and the prediction error of the proposed model are smaller than those of the other models for each motion state. As for Situation 2, except for the prediction error corresponding to the acceleration state, the performance of the proposed model is superior to that of the other models. These indicate that the proposed model has the best ability of extrapolation in the comparison, and it can well describe the relationship between the noise emission of electric vehicles and its relevant factors.

Table 8

The training errors and the prediction errors of the six models in Situation 1.

| Model | Constant-Speed State | Acceleration State | Deceleration State | |||

|---|---|---|---|---|---|---|

| Training Error | Prediction Error | Training Error | Prediction Error | Training Error | Prediction Error | |

| LR_2para | 2.44 | 2.18 | 2.12 | 1.42 | 1.68 | 2.09 |

| LR_1para | 2.44 | 2.18 | 2.12 | 1.50 | 1.92 | 2.72 |

| SVR | 3.33 | 4.87 | 3.09 | 3.18 | 2.42 | 5.25 |

| GPR | 3.20 | 5.24 | 2.72 | 4.14 | 2.34 | 5.39 |

| RF | 4.13 | 2.44 | 3.78 | 1.61 | 3.14 | 2.63 |

| MPR | 3.67 | 2.00 | 3.39 | 1.74 | 2.85 | 2.26 |

Table 9

The training errors and the prediction errors of the six models in Situation 2.

| Model | Constant-Speed State | Acceleration State | Deceleration State | |||

|---|---|---|---|---|---|---|

| Training Error | Prediction Error | Training Error | Prediction Error | Training Error | Prediction Error | |

| LR_2para | 2.40 | 2.65 | 2.01 | 2.49 | 1.48 | 4.34 |

| LR_1para | 2.40 | 2.65 | 2.04 | 2.25 | 1.69 | 4.99 |

| SVR | 3.24 | 4.31 | 3.15 | 3.68 | 2.97 | 2.47 |

| GPR | 3.13 | 5.06 | 2.76 | 4.74 | 2.84 | 2.59 |

| RF | 3.98 | 2.41 | 3.81 | 3.11 | 4.00 | 3.70 |

| MPR | 3.60 | 2.79 | 3.43 | 2.36 | 3.45 | 3.14 |

6. Conclusions

To present a better understanding of the traffic noise characteristics of electric vehicles, this study develops the traffic noise emission models of electric vehicles considering speed, acceleration, and motion state by a pass-by noise measurement experiment in Guangzhou, China. The results of the accuracy validation and the comparison between the six models indicate that the proposed models have the highest accuracy and the greatest ability of extrapolation and generalization, and they can provide a better description of the noise emission of electric vehicles. From the spectrum analysis, no matter what state electric vehicles are in, the speed and the acceleration have little effect on the low-frequency noise, but the noise at a certain frequency is most sensitive to the speed and the acceleration.

The limitation of this study is the insufficient consideration for the type of electric vehicles, which also determines the characteristics of noise emission. In future work, we will further investigate the effect of vehicle type on noise emission.

Acknowledgments

Comments and suggestions from the reviewers and editor are highly appreciated.

Funding Statement

The work described in this paper was funded by the National Environmental Protection Engineering and Technology Center for Road Traffic Noise Control, the Doctoral Point Construction Unit Research Capacity Enhancement Project (No. 22GPNUZDJS45), and the Science and Technology Planning Project of Guangzhou, China (No. 202102020314).

Author Contributions

Data curation, Z.L.; formal analysis, Z.L.; funding acquisition, F.L.; investigation, Z.L.; methodology, Z.L.; project administration, F.L.; software, Z.L.; supervision, M.Y., S.S. and F.L.; validation, Z.L.; visualization, Z.L.; writingoriginal draft, Z.L.; writingreview and editing, Z.L., M.Y., S.S. and F.L. All authors have read and agreed to the published version of the manuscript.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Conflicts of Interest

The authors declare no conflict of interest.

Footnotes

Disclaimer/Publishers Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

References

1.

Shamsipour M., Zaredar N., Monazzam M.R., Namvar Z., Mohammadpour S. Burden of diseases attributed to traffic noise in the metropolis of Tehran in 2017. Environ. Pollut. 2022;301:119042. doi:10.1016/j.envpol.2022.119042. [PubMed] [CrossRef] [Google Scholar]2.

Begou P., Kassomenos P. Exposure to the road traffic noise in an urban complex in Greece: The quantification of healthy life years lost due to noise-induced annoyance and noise-induced sleep disturbances. Environ. Sci. Pollut. Res. 2021;28:1293212943. doi:10.1007/s11356-020-11190-4. [PubMed] [CrossRef] [Google Scholar]3.

Riedel N., Kckler H., Scheiner J., Van Kamp I., Erbel R., Loerbroks A., Claen T., Bolte G. Urban road traffic noise and noise annoyanceA study on perceived noise control and its value among the elderly. Eur. J. Public Health. 2019;29:377379. doi:10.1093/eurpub/cky141. [PubMed] [CrossRef] [Google Scholar]4.

Baclet S., Venkataraman S., Rumpler R., Billsj R., Horvath J., sterlund P.E. From strategic noise maps to receiver-centric noise exposure sensitivity mapping. Transp. Res. Part D Transp. Environ. 2022;102:103114. doi:10.1016/j.trd.2021.103114. [CrossRef] [Google Scholar]5.

Cai M., Lan Z., Zhang Z., Wang H. Evaluation of road traffic noise exposure based on high-resolution population distribution and grid-level noise data. Build. Environ. 2019;147:211220. doi:10.1016/j.buildenv.2018.08.037. [CrossRef] [Google Scholar]6.

Faulkner J.-P., Murphy E. Road traffic noise modelling and population exposure estimation using CNOSSOS-EU: Insights from Ireland. Appl. Acoust. 2022;192:108692. doi:10.1016/j.apacoust.2022.108692. [CrossRef] [Google Scholar]7.

Yang W., He J., He C., Cai M. Evaluation of urban traffic noise pollution based on noise maps. Transp. Res. Part D: Transp. Environ. 2020;87:102516. doi:10.1016/j.trd.2020.102516. [CrossRef] [Google Scholar]8.

Li F., Lin Y., Cai M., Du C. Dynamic simulation and characteristics analysis of traffic noise at roundabout and signalized intersections. Appl. Acoust. 2017;121:1424. doi:10.1016/j.apacoust.2017.01.026. [CrossRef] [Google Scholar]9.

Wang H., Cai M., Luo W. Areawide dynamic traffic noise simulation in urban built-up area using beam tracing approach. Sustain. Cities Soc. 2017;30:205216. doi:10.1016/j.scs.2017.02.004. [CrossRef] [Google Scholar]10.

Asensio C., Pavn I., Ramos C., Lpez J.M., Pamis Y., Moreno D., de Arcas G. Estimation of the noise emissions generated by a single vehicle while driving. Transp. Res. Part D Transp. Environ. 2021;95:102865. doi:10.1016/j.trd.2021.102865. [CrossRef] [Google Scholar]11.

Lan Z., He C., Cai M. Urban road traffic noise spatiotemporal distribution mapping using multisource data. Transp. Res. Part D Transp. Environ. 2020;82:102323. doi:10.1016/j.trd.2020.102323. [CrossRef] [Google Scholar]12.

Lan Z., Cai M. Dynamic traffic noise maps based on noise monitoring and traffic speed data. Transp. Res. Part D Transp. Environ. 2021;94:102796. doi:10.1016/j.trd.2021.102796. [CrossRef] [Google Scholar]13.

Ercan T., Onat N.C., Keya N., Tatari O., Eluru N., Kucukvar M. Autonomous electric vehicles can reduce carbon emissions and air pollution in cities. Transp. Res. Part D Transp. Environ. 2022;112:103472. doi:10.1016/j.trd.2022.103472. [CrossRef] [Google Scholar]14.

Lan Z., Cai M., Li F., Yang W. Study of the Traffic Noise Source Emission Model and the Frequency Spectrum Analysis of Electric Vehicles on Urban Roads in China. Acta Acust. United Acust. 2018;104:989998. doi:10.3813/AAA.919265. [CrossRef] [Google Scholar]15.

Department of Transport . Calculation of Road Traffic Noise. HMSO; Welsh, UK: 1988. [Google Scholar]16.

Richtlinien fr den Lrmschutzan Strassen-RLS-90. BM fr Verkehr, Bonn. 1990. [(accessed on 28 June 2006)]. Available online: https://www.gesetze-bayern.de/17.

Besnard F., Hamet J.F., Lelong J., Le Duc E., Guizard V., Frst N., Doisy S., Dutilleux G. Road Noise Prediction, 1Calculating Sound Emissions from Road Traffic. Methodologic Guide; Cerema, Centre dtudes et dexpertise sur les risques, lenvironnement, la mobilit et lamnagement (Administration) [(accessed on 1 June 2009)]. Available online: https://doc.cerema.fr/Default/digital-viewer/C-1754718.

Hamet J.-F., Besnard F., Doisy S., Lelong J., Le Duc E. New vehicle noise emission for French traffic noise prediction. Appl. Acoust. 2010;71:861869. doi:10.1016/j.apacoust.2010.05.003. [CrossRef] [Google Scholar]19.

Jonasson H., Sandberg U., Blokland G.V., Ejsmont J., Watts G., Luminari M. Harmonoise. Work Package 1.1. Deliverable 9: Source Modelling of Road Vehicles. The National Academies of Sciences, Engineering, and Medicine; Washington, DC, USA: 2004. [Google Scholar]20.

Watts G. Harmonoise Prediction Model for Road Traffic Noise. Acoust. Bull. 2005;30:1921, 2325. [Google Scholar]21.

Yamamoto K. Road traffic noise prediction model ASJ RTN-Model 2008: Report of the Research Committee on Road Traffic Noise. Acoust. Sci. Technol. 2010;31:255. doi:10.1250/ast.31.2. [CrossRef] [Google Scholar]22.

Sakamoto S. Road traffic noise prediction model ASJ RTN-Model 2018: Report of the Research Committee on Road Traffic Noise. Acoust. Sci. Technol. 2020;41:529589. doi:10.1250/ast.41.529. [CrossRef] [Google Scholar]24.

Fleming G., Rapoza A., Lee C. Development of National Reference Energy Mean Emission Levels for the FHWA Traffic Noise Model, Version 1.0. Office of Engineering and Highway Operations Research and Development; Washington, DC, USA: 2005. Publication No. DOT-VNTSC-FHWA-96-2. [Google Scholar]25.

Menge C.W., Rossano C.F., Anderson G.S., Bajdek C.J. FHWA Traffic Noise Model. U.S. Department of Transportation, Federal Highway Administration; Washington, DC, USA: 1996. FHWA-PD-96-010. [Google Scholar]26.

Can A., Aumond P. Estimation of road traffic noise emissions: The influence of speed and acceleration. Transp. Res. Part D Transp. Environ. 2018;58:155171. doi:10.1016/j.trd.2017.12.002. [CrossRef] [Google Scholar]27.

Pascale A., Fernandes P., Guarnaccia C., Coelho M. A study on vehicle Noise Emission Modelling: Correlation with air pollutant emissions, impact of kinematic variables and critical hotspots. Sci. Total. Environ. 2021;787:147647. doi:10.1016/j.scitotenv.2021.147647. [CrossRef] [Google Scholar]28.

Peng J., Liu D., Parnell J., Kessissoglou N. Influence of translational vehicle dynamics on heavy vehicle noise emission. Sci. Total. Environ. 2019;689:13581369. doi:10.1016/j.scitotenv.2019.06.426. [PubMed] [CrossRef] [Google Scholar]29.

Peng J., Parnell J., Kessissoglou N. A six-category heavy vehicle noise emission model in free-flowing condition. Appl. Acoust. 2019;143:211221. doi:10.1016/j.apacoust.2018.08.030. [CrossRef] [Google Scholar]30.

Snchez-Fernndez M., Morillas J.M.B., Gonzlez D.M., Gozalo G.R. Relationship between temperature and road traffic noise under actual conditions of continuous vehicle flow. Transp. Res. Part D Transp. Environ. 2021;100:103056. doi:10.1016/j.trd.2021.103056. [CrossRef] [Google Scholar]31.

Cai M., Zhong S., Wang H., Chen Y., Zeng W. Study of the traffic noise source intensity emission model and the frequency characteristics for a wet asphalt road. Appl. Acoust. 2017;123:5563. doi:10.1016/j.apacoust.2017.03.006. [CrossRef] [Google Scholar]32.

Abdur-Rouf K., Shaaban K. Development of prediction models of transportation noise for roundabouts and signalized intersections. Transp. Res. Part D Transp. Environ. 2022;103:103174. doi:10.1016/j.trd.2022.103174. [CrossRef] [Google Scholar]33.

Gardziejczyk W., Motylewicz M. Noise level in the vicinity of signalized roundabouts. Transp. Res. Part D: Transp. Environ. 2016;46:128144. doi:10.1016/j.trd.2016.03.016. [CrossRef] [Google Scholar]34.

Khajehvand M., Rassafi A.A., Mirbaha B. Modeling traffic noise level near at-grade junctions: Roundabouts, T and cross intersections. Transp. Res. Part D Transp. Environ. 2021;93:102752. doi:10.1016/j.trd.2021.102752. [CrossRef] [Google Scholar]35.

Yadav A., Mandhani J., Parida M., Kumar B. Modelling of traffic noise in the vicinity of urban road intersections. Transp. Res. Part D: Transp. Environ. 2022;112:103474. doi:10.1016/j.trd.2022.103474. [CrossRef] [Google Scholar]36.

Chen L., Tang B., Liu T., Xiang H., Sheng Q., Gong H. Modeling traffic noise in a mountainous city using artificial neural networks and gradient correction. Transp. Res. Part D Transp. Environ. 2020;78:102196. doi:10.1016/j.trd.2019.11.025. [CrossRef] [Google Scholar]37.

Baccoli R., Sollai F., Medda A., Piccolo A., Fadda P. An adaptive nonlinear autoregressive ANN model for high time resolution traffic noise predictions. Experimental results for a port city waterfront. Build. Environ. 2022;207:108551. doi:10.1016/j.buildenv.2021.108551. [CrossRef] [Google Scholar]38.

Fallah-Shorshani M., Yin X., McConnell R., Fruin S., Franklin M. Estimating traffic noise over a large urban area: An evaluation of methods. Environ. Int. 2022;170:107583. doi:10.1016/j.envint.2022.107583. [PubMed] [CrossRef] [Google Scholar]39.

Abo-Qudais S., Alhiary A. Statistical models for traffic noise at signalized intersections. Build. Environ. 2007;42:29392948. doi:10.1016/j.buildenv.2005.05.040. [CrossRef] [Google Scholar]40.

Li F., Liao S.S., Cai M. A new probability statistical model for traffic noise prediction on free flow roads and control flow roads. Transp. Res. Part D: Transp. Environ. 2016;49:313322. doi:10.1016/j.trd.2016.10.019. [CrossRef] [Google Scholar]41.

Li F., Xue W., Rong Y., Du C., Tang J., Zhao Y. A probability distribution prediction method for expressway traffic noise. Transp. Res. Part D: Transp. Environ. 2022;103:103175. doi:10.1016/j.trd.2022.103175. [CrossRef] [Google Scholar]42.

Pallas M.-A., Brengier M., Chatagnon R., Czuka M., Conter M., Muirhead M. Towards a model for electric vehicle noise emission in the European prediction method CNOSSOS-EU. Appl. Acoust. 2016;113:89101. doi:10.1016/j.apacoust.2016.06.012. [CrossRef] [Google Scholar]43.

Cesbron J., Bianchetti S., Pallas M.-A., Le Bellec A., Gary V., Klein P. Road surface influence on electric vehicle noise emission at urban speed. Noise Mapp. 2021;8:217227. doi:10.1515/noise-2021-0017. [CrossRef] [Google Scholar]44.

Pallas M., Chatagnon R., Lelong J. Noise emission assessment of a hybrid electric mid-size truck. Appl. Acoust. 2014;76:280290. doi:10.1016/j.apacoust.2013.08.012. [CrossRef] [Google Scholar]45.

Czuka M., Pallas M.A., Morgan P., Conter M. Impact of Potential and Dedicated Tyres of Electric Vehicles on the Tyre-road Noise and Connection to the EU Noise Label. Transp. Res. Procedia. 2016;14:26782687. doi:10.1016/j.trpro.2016.05.443. [CrossRef] [Google Scholar]46.

Yang W., Lan Z., Wang H., Cai M. Case study: Establishment of a vehicle noise emission model for gradient roads. Noise Control. Eng. J. 2019;67:108116. doi:10.3397/1/376710. [CrossRef] [Google Scholar]48.

Platt J. Probabilistic Outputs for Support Vector Machines and Comparison to Regularized Likelihood Methods. Advances in Large Margin Classifiers. 1999. [(accessed on 26 March 1999)]. Available online: https://citeseerx.ist.psu.edu/doc/10.1.1.41.163949.

Rasmussen C.E. Gaussian Processes in Machine Learning. Summer School on Machine Learning. Springer; Berlin/Heidelberg, Germany: 2003. [Google Scholar]50.

Breiman L. Random Forests. Mach. Learn. 2001;45:532. doi:10.1023/A:1010933404324. [CrossRef] [Google Scholar]51.

Glorot X., Bengio Y. Understanding the difficulty of training deep feedforward neural networks; Proceedings of the International Conference on Artificial Intelligence and Statistics; Sardinia, Italy. 1315 May 2010. [Google Scholar]