The EV Technology Landscape From Batteries to Autonomous Features

EV landscape 2024: Tech evolution & battery intelligence

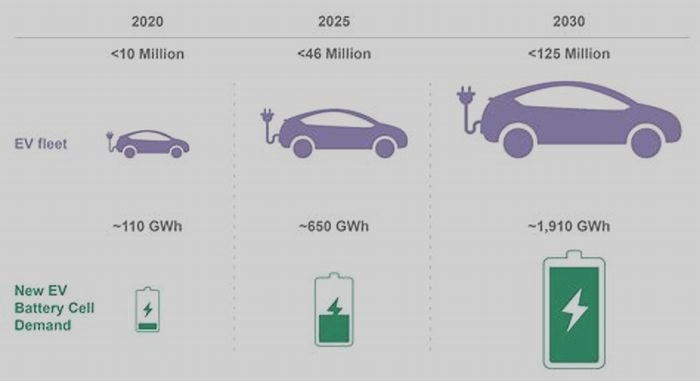

Electronics manufacturers are working hard to build more efficient EV batteries, with drivers repeatedly citing range anxiety as a reason for their decision not to switch to an electric vehicle.

Last week, Rho Motion revealed that North America is close to overtaking Europe, in the race to who can offer the lowest prices for electric vehicles. Rho Motion - which provides forecasts on the energy transition and development of batteries - has suggested that EV consumers in the USA will be paying less for a new EV than their European counterparts, by January 2024.

Electronics manufacturer Brill Power is on a mission to transform battery management systems and reduce the costs of batteries and sustainable technology for consumers. The company is based in Oxford, UK and was founded in 2016. Peter Freedman, Chief Commercial Officer at Brill Power, shared his thoughts on battery production exclusively with EV Magazine.

2024 Outlook: Shifting trends in EV landscape and the rise of battery intelligence

Following the Automated Vehicles Bill and the release of the UKs inaugural EV battery strategy this month, Freedman says a stronger roadmap for EV initiatives is expected from governments across the world, in addition to the biggest manufacturers, in 2024.

In the past few years, UK players have intensified investments to stay competitive with global markets like China and South Korea. However, inflation, combined with the surge in interest rates has led to a deceleration in the growth of EV demand, as consumers await more affordable options. Consequently, UK and European players are poised to adopt a more judicious approach to their EV investments.

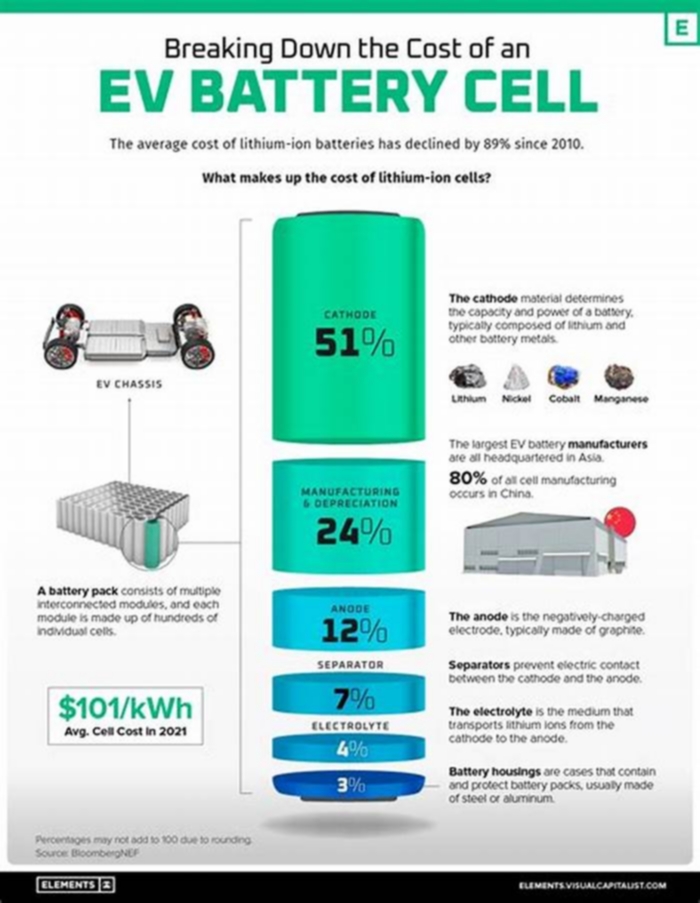

This shift is exemplified by the dwindling enthusiasm for fully autonomous vehicles, with major automakers redirecting their focus towards competitively priced Battery Electric Vehicles (BEVs). As a ripple effect, the expansion of the battery supply chain and decreasing raw material costs are expected to drive down battery pricing per kWh. Our Battery Intelligence Platform at Brill Power plays a pivotal role in intelligently managing batteries, optimising energy usage, and extending the lifespan of EV batteries.

In the wake of narrowing margins in the race for electrification and autonomy and setbacks like those experienced by Cruise, top-tier automakers are likely to witness a squeeze on profit margins. Discounting is becoming more prevalent in the EV sector as OEMs look to move EV stock to ensure capacity is fulfilled at manufacturing facilities. Interestingly, this situation creates an opportunity for international players such as China's BYD to fortify their presence in the UK and European markets, mirroring their success in the bus industry through well-priced offerings which leverage their scale and vertical integration throughout the battery supply chain."

Toyota Unveils New Technology That Will Change the Future of CarsPioneering the future with the power of technology, centered on innovative battery EV technology and the establishment of a hydrogen business

To respond to the rapid changes in the market, we will establish a new organization called Hydrogen Factory in July, which will be able to make immediate decisions under one leader, from sales to development and production, all at once. The Hydrogen Factory will promote business on three axes.

The first is localizing R&D and production in countries within the major markets. We will accelerate our efforts by establishing local bases, mainly in Europe and China.

The second is strengthening alliances with leading partners. We will do our best to deliver affordable fuel cells to our customers by consolidating sufficient quantities through alliances.

The third is competitiveness and technology.

We will work on "innovative evolution of competitive next-generation FC technologies," such as next-generation cell technologies and FC systems.

The Role of AI in EV Battery Technology (Part II)

(Austin, Texas) Al is here to stay and so is the EV industry. AI plays a significant role in autonomous driving and battery capabilities. This article will explore how a complex web of factors (which includes AI), makes EV batteries, especially Tesla EV batteries, much safer than ever imagined. This is a follow-up to Part I, which focuses on AI in EV autonomous driving.

Much of this article focuses on Tesla. We know Tesla sets the gold standard for real-world AI with specialized algorithms, code foundations, evaluation infrastructure, and the Dojo system. But did you know that Tesla also sets the standard for battery technology which includes AI?

To understand this better, I will start by sharing with you my personal experience with everyday battery management in my Model Y.

Battery Charging

Every morning, I wake up to a full battery in my Model Y. The battery charges when my local utility rates are at their lowest during the night. Imagine gasoline prices gradually lowering at certain times of the night because of less demand. Well, electricity is cheaper at night, so when charging at night you pay less. But what about if you cannot charge at home or you live in an apartment with no charging? Tesla offers lower Supercharger rates at off-peak times.

For illustration purposes, here is a screen capture of my Model Y UI to show you some of the information you have at your fingertips.

A close look shows that at the Austin, Texas Supercharger at Research, from 4:00 am to 1:00 pm, supercharging costs $0.28 per kWh. As a result of factors such as the cost of electricity in Texas at this location, these rates are adjusted. In addition, they reflect the demand for charging at this location. If you really want to save money, you could plan to charge here from 12:00 a.m. to 4:00 when rates are only $0.13 per kWh. However, if you must charge when demand is high, you will pay $0.40 per kWh from 1:00 p.m. to 8:00 p.m.

With a little planning, supercharging does not have to be expensive. Supercharging pricing uses Teslas AI to quickly determine, in real-time, local prices, and local demand. Thus, supercharging times and prices will vary quite a bit from location to location. Supercharger details can be accessed on your Tesla screen. You can plan out a trip and look ahead to see how many empty spots are available for charging. In the above example, there are 18 stalls and 14 are available.

Teslas AI knows exactly when to charge with Trip Planner.

Battery Charging Safety and Trip Planner

Tesla uses advanced AI-driven software to keep your vehicles battery charged on trips in the safest way possible. When you need to Supercharge, and when you are at the optimal distance from a Supercharger, your Teslas battery preconditions automatically.

Tesla recommends Trip Planner (available in most markets) for longer journeys. This feature uses AI to navigate to a charging location and at least 30-45 minutes before arrival, the battery will start preconditioning. This ensures optimal battery temperature and charging conditions.

In South Texas, I used Trip Planner for several road trips to see the Starship. When I travel, Trip Planner routes me to the appropriate Superchargers. To minimize the amount of time I spend driving and charging, Trip Planner selects a route and provides charging times. To enable Trip Planner, click the map's settings icon and select Trip Planner.

When Trip Planner is enabled and charging is required to reach a destination, the turn-by-turn direction list includes Supercharger stops, recommended charging times at each Supercharger, and an estimate of how much energy will be available when you arrive at the Supercharger location.

By using Trip Planner to navigate to a Tesla charging location, the AI software ensures the high-voltage battery is pre-conditioned to ensure when you arrive at the charger, the battery temperature is optimal and ready to charge. This reduces the amount of time it takes to charge and maintains a healthy battery.

Tesla is constantly improving and testing under extreme conditions.

Tesla's High Voltage Battery Design Engineering Team uses real-world testing and AI

To make your vehicle's battery as high-performing as possible, talented engineers and artificial intelligence work together as part of a " width="50"cybernetic collective." Engineers work in a factory environment, not a pristine office. Among the cross-functional problems in design or manufacturing, batteries require structural, thermal, electrical, and sensing components and are made of hundreds of cells. Since batteries are made 24/7, the continued ramp, stabilization, optimization, and holistic sustaining of battery components & assemblies is a challenging job. Tesla is continually launching various improvement efforts to refine the product, and AI plays a big role in these efforts through QC, design optimization, and data analysis.

Quality Control. AI is used for quality control during the manufacturing process. It inspects components and assemblies for defects or deviations from desired specifications and ensures batteries meet strict quality standards.

Design Optimization. AI assists in the design process by rapidly simulating and evaluating various design options. It analyzes structural, thermal, and electrical components to optimize battery performance and efficiency.

Data Analysis. AI processes and analyzes large volumes of data generated during testing and production. This identifies patterns, anomalies, and areas for improvement faster and more accurately than manual analysis.

Tesla's Battery Testing and AI Integration

Tesla's commitment to battery improvement is an ongoing endeavor, leveraging AI technology to increase the safety of its entire fleet of millions of cars. Within Teslas "Abuse Testing & Engineering Group," Tesla rigorously challenges battery systems, pushing them beyond their limits with specialized equipment, and subjecting them to electrical, mechanical, and thermal stresses. This rigorous testing, enhanced by AI technology, is aimed at rapidly acquiring valuable insights that can shape early design decisions. Tesla seeks to understand how robust their systems are when subjected to extreme conditions, a process commonly referred to as "testing to failure."

Tesla battery products, whether for their vehicles or energy storage solutions, undergo this demanding process. The pace is relentless, ensuring that every battery product that emerges from this environment is thoroughly vetted. In addition, AI technology plays a crucial role in data analysis and safety assessment.

A dedicated team of engineers and technicians conduct large-scale, thermally destructive tests in the lab, enhanced by AI, to guarantee that the batteries meet the highest safety standards for all customers. Tesla's approach isn't just about executing complex tests flawlessly; it's also about distilling the results, with AI, into a wealth of knowledge that improves future batteries.

My thoughts

In my old gasoline car, I relied on my iPhone for maps and the tank indicator to see when I needed to re-fuel and prices were the same at night as in the daytime. My Model Y provides a feeling of living in the future through the seamless integration of many factors. The batteries are heavy, with a low center of gravity, making the vehicle feel like it drives on rails. The maps sense distance, need to charge, and take into account traffic in Austin, re-routing the car as appropriate. I do not pay a premium to charge at home or on off-peak hours at a Supercharger. Though I do not consciously think about how much painstaking effort in put into the battery and its many functions, there is a team at Tesla. Tesla's AI supports the team and has one goal: Making the most advanced batteries possible.

If you want to take advantage of a program to provide a valuable warranty on your Teslas battery, check out Xcelerate.

MIT Technology Review

Solid-state batteries can use a wide range of chemistries, but a leading candidate for commercialization uses lithium metal. Quantumscape, for one, is focused on that technology and raised hundreds of millions in funding before going public in 2020. The company has a deal with Volkswagen that could put its batteries in cars by 2025.

But completely reinventing batteries has proved difficult, and lithium-metal batteries have seen concerns about degradation over time, as well as manufacturing challenges. Quantumscape announced in late December it had delivered samples to automotive partners for testing, a significant milestone on the road to getting solid-state batteries into cars. Other solid-state-battery players, like Solid Power, are also working to build and test their batteries. But while they could reach major milestones this year as well, their batteries wont make it into vehicles on the road in 2023.

Solid-state batteries arent the only new technology to watch out for. Sodium-ion batteries also swerve sharply from lithium-ion chemistries common today. These batteries have a design similar to that of lithium-ion batteries, including a liquid electrolyte, but instead of relying on lithium, they use sodium as the main chemical ingredient. Chinese battery giant CATL reportedly plans to begin mass-producing them in 2023.

Sodium-ion batteries may not improve performance, but they could cut costs because they rely on cheaper, more widely available materials than lithium-ion chemistries do. But its not clear whether these batteries will be able to meet needs for EV range and charging time, which is why several companies going after the technology, like US-based Natron, are targeting less demanding applications to start, like stationary storage or micromobility devices such as e-bikes and scooters.

Today, the market for batteries aimed at stationary grid storage is smallabout one-tenth the size of the market for EV batteries, according to Yayoi Sekine, head of energy storage at energy research firm BloombergNEF. But demand for electricity storage is growing as more renewable power is installed, since major renewable power sources like wind and solar are variable, and batteries can help store energy for when its needed.

Lithium-ion batteries arent ideal for stationary storage, even though theyre commonly used for it today. While batteries for EVs are getting smaller, lighter, and faster, the primary goal for stationary storage is to cut costs. Size and weight dont matter as much for grid storage, which means different chemistries will likely win out.

One rising star in stationary storage is iron, and two players could see progress in the coming year. Form Energy is developing an iron-air battery that uses a water-based electrolyte and basically stores energy using reversible rusting. The company recently announced a $760 million manufacturing facility in Weirton, West Virginia, scheduled to begin construction in 2023. Another company, ESS, is building a different type of iron battery that employs similar chemistry; it has begun manufacturing at its headquarters in Wilsonville, Oregon.

Shifts within the standard

Lithium-ion batteries keep getting better and cheaper, but researchers are tweaking the technology further to eke out greater performance and lower costs.