The Environmental Impact of Electric Vehicles A Life Cycle Assessment

Life cycle environmental impact assessment for battery-powered electric vehicles at the global and regional levels

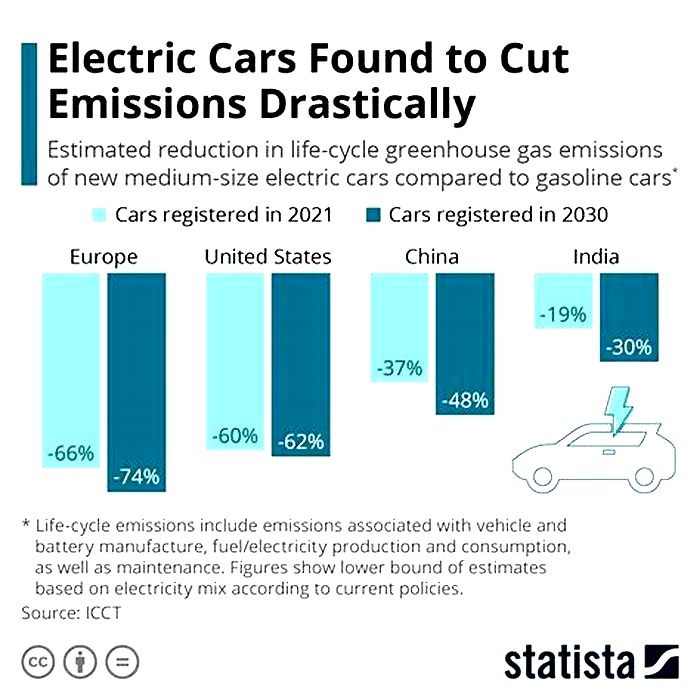

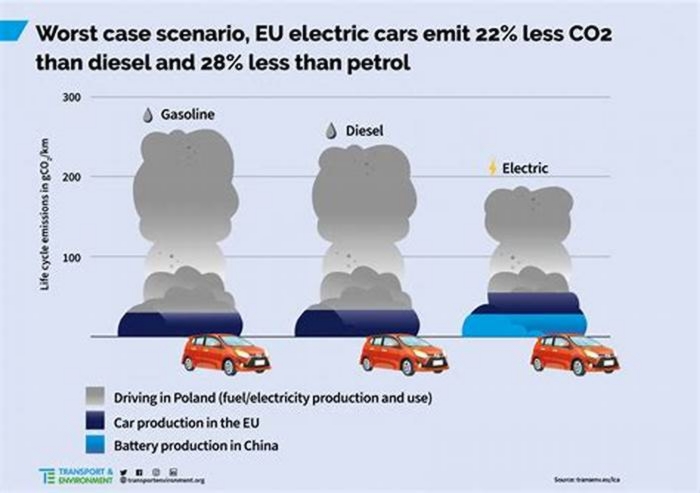

Due to the different power structures in different regions, the decarbonization capacity of the power sector is not consistent, and the environmental impacts are also discrepant. In the use stage, this work assumes that the EV travels in five different regions to analyze the influence of regional power structure on the environmental characteristics of the battery pack. Compared with other models, the mini-car has the characteristics of smaller battery capacity, less energy demand, miniaturization and convenience, which is suitable for short distance driving and conducive to promotion. Therefore, this study only explored the comprehensive environmental impact of mini EVs (the mini-car weighs 1100kg, the battery capacity is 17.7kWh, and the energy demand is 96.8Whkm1).

LCA method

As a scientific method to evaluate the energy demand and the emissions associated with products life cycles28, LCA has been widely used in product environmental characteristic analysis and decision support. LCA is divided into four stages: objective and scope determination, inventory analysis, evaluation impact analysis and results, and interpretation or optimization of evaluation results29. In this study, the footprint family, resource depletion and toxic damage of EV battery packs were evaluated comprehensively by the LCA method.

In this study, 11 kinds of batteries were selected as research objects to analyze their environmental impact under the power structure in 5 regions. The scope of the study is the EV use process, which does not involve the production of the car and battery but only the process of charging the battery and running the car on the road. A certain distance was taken as the evaluation unit of the environmental impact of the battery. When the EV of different batteries travels the same mileage, their respective battery capacity is different. The power comes from the electric energy that the EV absorbs while charging. That power, in turn, comes from energy sources such as coal, nuclear or hydropower. Therefore, it can be seen that a certain driving distance, under the support of different batteries, can correspond to their respective power. Therefore, we define the functional unit as the distance traveled per unit.

Since the commonly used commercial battery pack types are LFP and NMC, two kinds of LFP (according to the different compositions and proportions of LFP cathode materials), three kinds of NMC (according to the different composition ratios of the three active materials of nickel, cobalt and manganese and the different proportions of cathode materials) and two kinds of NMC batteries combined with nanoanode materials (silicon nanowires and silicon nanotubes) were selected. In addition, one kind of battery pack with LMO as a positive active material, one kind of composite cathode material battery containing LMO and NMC and two kinds of LIBs containing sulfur were also selected. Therefore, the research objects of this study were eleven different types of LIB packs, including LFPx-C30, LFPy-C31, NMC-C31, NMC442-C30, NMC111-C32, NMC-SiNT33, NMC-SiNW34, LMO-C35, LMO/NMC-C36, Li-S37 and FeS2SS38.

Battery packs can be divided into four categories according to their components, namely LFP, NMC, LMO and LMB. Specific information:

LFP: LFPx-C, lithium iron phosphate oxide battery with graphite for anode,its batterypackenergydensity was 88 Whkg1 and chargedischargeenergyefficiency is 90%; LFPy-C, lithium iron phosphate oxide battery with graphite for anode, x and y only represent different battery types, its chargedischarge efficiency is 95% and electricity consumption is 15kWh per 100km.

NMC: NMC-C, lithium-nickel manganese cobalt oxide (LiNixMnyCo (1-xy) O2) coupled with a graphite anode material, its chargedischarge efficiency is 99% and electricity consumption was 13kWh per 100km; NMC442-C, lithium-nickel manganese cobalt oxide (LiNi0.4Mn0.4Co0.2O2) coupled with a graphite anode material, battery pack energy density is 112Whkg1 and chargedischarge energy efficiency is 90%; NMC111-C, lithium-nickel manganese cobalt oxide (LiNi0.33Mn0.33Co0.33O2) coupled with a graphite anode material, its energy capacity is 26.6kWh and battery efficiency is 95% to 96%; NMC-SiNT, lithium-nickel manganese cobalt oxide (LiNixMnyCo (1-xy) O2) coupled with a silicon nanotube anode material, its gravimetric energy density is 199Whkg1 and chargedischarge efficiency is 90%; NMC-SiNW, lithium-nickel manganese cobalt oxide (LiNixMnyCo (1-xy) O2) coupled with a silicon nanowire anode material, the battery pack has a total weight of 120kg and energy capacity of 43.2kWh.

LMO: LMO-C, lithium manganese oxide (LiMn2O4) coupled with a graphite anode material, the battery weight is 300kg and the battery capacity was 34.2kWh; LMO/NMC-C, lithium manganese oxide coupled with a graphite anode material (LiMn2O4 and LiNi0.4Mn0.4Co0.2O2), the nominal capacity of which is 11.4kWh and can to be used for approximately 140,000km of driving;

LMB: LiS, lithium metal coupled with elemental sulfur, its total energy capacity is 61.3kWh and charging efficiency is 95%; FeS2SS, solid-state lithium battery with iron sulfide (FeS2) for cathode; lithium metal for the anode; and lithium sulfide (Li2S) and phosphorous pentasulfide (P2S5) for solid-state electrolyte, its specific capacity of 182Whkg1 and energy capacity is 80kWh.

Studies assessing the environmental impacts of LIBs assume total driving distances between 150,000km and 200,000 km34. In this study, it is assumed that the EVs battery has a serves range of 180,000km, and no replacement of batteries is considered during the use period. The boundary range of the study is the use stage of the battery pack, so the functional unit is determined to be 1km, that is, the environmental impact of the power battery pack in the use stage is calculated based on the unit running distance. The basic scenario parameters are listed in Table 1.

Power structure and operation calculation of the power battery pack in the use phase

In the operation phase, the regional analysis emphasizes the difference in the influence of different power combinations on the analysis results. Therefore, in the use of EV battery packs, the power supply structure will affect the environmental emissions to a large extent. The regions of the use stage of EV are determined in five regions for analysis, including Global, China, Japan, Europe and the US.

In the use stage, the power loss of the battery (to provide power for EV transportation), the extra power required by the vehicle to transport the battery, and the energy consumed during the vehicle operation were considered. The battery usage process is calculated based on the assumptions of the base scenario (Table 1).

Power loss (({EL}_{be})) due to battery charging efficiency:

$${EL}_{be}={D}_{v}times {CEL}_{drm}times (1-eta c)$$

(1)

where ({EL}_{be}) represents the power loss caused by battery charging, kWh; ({D}_{v}) is the mileage of the electric vehicle, km; and ({CEL}_{drm}) represents EV's power consumption per kilometer, kWhkm1.(eta c) is the efficiency of a battery, %.

Extra power (ELex) from the transportation of battery:

$${EL}_{ex}={W}_{b}/{W}_{v}times {CEL}_{w}times {CEL}_{drm}/eta ctimes {D}_{v}$$

(2)

where ({EL}_{ex}) represents the extra power required to transport the battery, kWh; ({W}_{b}) is the weight of the battery pack, kg; ({W}_{v}) is the weight of the EV, kg; and ({CEL}_{w}) represents the direct relationship between energy consumption and battery transport (weight-energy ratio: 30% in the base scenario), %.

The energy consumed (ELu)during battery life is:

$${EL}_{u}={CA}_{b}times INT({D}_{v}/{D}_{r})$$

(3)

where Elu represents the energy consumed during battery life, kWh; ({CA}_{b}) is battery pack capacity, kWh; and ({D}_{r}) stands for the mileage of EV in a cycle, kmcharge1.

The energy in the use stage of the battery pack consists of power loss, extra power and power consumption. The frame diagram of the use phase and electricity generation structure in different regions in 2018 are shown in Fig.2.

The frame diagram of the use phase and electricity generation structure in different regions in 2018 (Data source: http://bp.com/statsreview).

According to the above formula, the total electric energy consumed by electric vehicles in the driving stage is calculated, and then fed into Simapro software. According to the power structure of different regions, the three-level index value of emissions in the power generation process can be calculated.

Comprehensive environmental assessment indicators

In this study, by referring to domestic and foreign literature, 11 groups of representative three-level indicators were selected and divided into three groups of second-level comprehensive indicators: resource depletion, footprint family and toxic damage. The comprehensive environmental assessment index is shown in Fig.3.

Comprehensive environmental assessment index.

Calculation of index weight

To evaluate the environmental characteristic of the battery pack as a whole, a comprehensive index, namely, the environmental characteristic index, was constructed on the basis of the second-level indicators, such as footprint family, resource depletion and toxic damage.

In the multi-index evaluation system, it is often inconvenient to compare and analyze the indexes because of the different units, dimensions and orders of magnitude of each index. Unified data processing can prevent different dimensions of the main indicators from affecting the evaluation results. As seen from the indicators of the comprehensive environmental evaluation system constructed, the indicators in the system are all reverse indicators, and the positive standardized formula is:

$${Z}_{ij}=frac{underset{1ll ill n}{mathrm{max}}{X}_{ij}-{X}_{ij}}{underset{1ll ill n}{mathrm{max}}{X}_{ij}-underset{1ll ill n}{mathrm{min}}{X}_{ij}};$$

(4)

In the formula, ({X}_{ij}) represents the original data of the jth third-level index of the ith battery. i stands for different types of power packs (i=1,211). j is the category of index data (j=1, 2 11). ({Z}_{ij}) is the standardized value of the jth index of the ith type battery. Among them, the value of ({Z}_{ij}) ranges from 0 to 1. The larger the value is, the better the data of this indicator will be.

The entropy weight method is an objective weight method. In the specific process of use, the entropy weight of each index is calculated by using information entropy according to the degree of data dispersion of each index, and then the entropy weight is modified according to each index to obtain a relatively objective weight of the index. Entropy is used to measure the disorder degree of the system, as well as the effective information carried by the data, to determine the weight value of the index. If the information entropy of the index is smaller, it means that the variation degree of the index value is larger, and the information provided by the index is more, so it should play a greater role in the comprehensive evaluation, and the weight is higher. In this study, the introduction of weight did not change the basic research method, but sorted out the calculation results of LCA, to conduct an overall analysis of the battery pack environmental impact and make the results more accurate.

The information entropy of a set of data is:

$${S}_{j}=-mathrm{ln}left(frac{1}{n}right)sum_{i=1}^{n}{P}_{ij}mathrm{ln}{P}_{ij}$$

(5)

where ({P}_{ij}=frac{{Z}_{ij}}{{sum }_{i=1}^{n}{Z}_{ij}}), if ({P}_{ij}=0), (underset{{mathrm{P}}_{mathit{ij}}to 0}{mathrm{lim}}{P}_{ij}mathrm{ln}{P}_{ij}=0)

The corresponding weight of the indicator is:

$${y}_{j}=frac{1-{S}_{j}}{m-{sum }_{j=1}^{m}{S}_{j}}$$

(6)

where ({S}_{j}) is the information entropy of a set of data and ({y}_{j}) is the corresponding weight of the indicator.

The entropy weight method is used to calculate the weight of each environmental index. Figure4 shows the indicator combinations and their weight values of global regional environmental characteristic indicators.

Indicator combinations and their weight values of global regional environmental characteristics indicators.

Among the 11 third-level indicators, the weight value of the carbon footprint is the largest and that of POFP is the smallest, indicating that carbon footprint is one of the important reference indexes of environmental performance in the environmental impact assessment of battery packs.

The 11 impact indicators are the reflection of the battery emission potential in their respective fields. The environmental characteristic index reflects the comprehensive environmental impact of the battery pack in the use stage, that is, the cleanliness degree of the 11 impact indicators on the overall environmental condition. The higher the environmental characteristic index, the smaller the negative impact of the battery pack on the natural environment, that is, the cleaner the driving process. The calculation method of the environmental characteristic index is as follows:

$${E}_{i}=sum_{j=1}^{m}{y}_{j}{Z}_{ij}$$

(7)

where ({E}_{i}) is the environmental characteristic index of the ith battery pack.

Life cycle assessment of electric vehicles: a systematic review of literature

Abdallah L, El-Shennawy T (2013) Reducing carbon dioxide emissions from electricity sector using smart electric grid applications. J Eng 2013

Abdul-Manan AFN (2015) Uncertainty and differences in GHG emissions between electric and conventional gasoline vehicles with implications for transport policy making. Energy Policy 87:17. https://doi.org/10.1016/j.enpol.2015.08.029

Article Google Scholar

Accardo A, Dotelli G, Musa ML, Spessa E (2021) Life cycle assessment of an NMC battery for application to electric light-duty commercial vehicles and comparison with a sodium-nickel-chloride battery. Appl Sci 11(3):1160. https://doi.org/10.3390/app11031160

Article CAS Google Scholar

Aichberger C, Jungmeier G (2020) Environmental life cycle impacts of automotive batteries based on a literature review. Energies 13. https://doi.org/10.3390/en13236345

Andersson , Brjesson P (2021) The greenhouse gas emissions of an electrified vehicle combined with renewable fuels: life cycle assessment and policy implications. Appl Energy 289. https://doi.org/10.1016/j.apenergy.2021.116621

Asaithambi G, Treiber M, Kanagaraj V (2019) Life cycle assessment of conventional and electric vehicles. International climate protection. Springer, Cham, pp 161168

Chapter Google Scholar

Aswani R, Sajith S, Bhat MY (2021) Is geopolitics a threat for offshore wind energy? A case of Indian Ocean Region. Environ Sci Pollut Res 28:3268332694. https://doi.org/10.1007/s11356-021-12779-z

Article Google Scholar

Ayodele BV, Mustapa SI (2020) Life cycle cost assessment of electric vehicles: a review and bibliometric analysis. Sustainability 12. https://doi.org/10.3390/su12062387

Balpreet, K. (2018). Life cycle analysis of electric vehiclesquantifying the impact. Technical Report. 2018. Available online: https://sustain.ubc.ca/sites/default/files/2018-63%20Lifecycle%20Analysis%20of%20Electric%20Vehicles_Kukreja.pdf. Accessed 12 Jan 2022

Benveniste G,SnchezA, Rallo H, Corchero C, Amante B (2022) Comparative life cycle assessment of Li-sulphur and Li-ion batteries for electric vehicles. Resour Conserv Recycl Adv 200086. https://doi.org/10.1016/j.rcradv.2022.200086

Bhat MY, Sofi AA, Sajith S (2022) Domino-effect of energy consumption and economic growth on environmental quality: role of green energy in G20 countries. Manag Environ Qual An Int J. https://doi.org/10.1108/MEQ-08-2021-0194

Article Google Scholar

Bieker G (2021) A global comparison of the life-cycle greenhouse gas emissions of combustion engine and electric passenger cars. Communications 49(30):847129847102

Google Scholar

Brysse K, Oreskes N, Oreilly J, Oppenheimer M (2013) Climate change prediction: erring on the side of least drama? Glob Environ Chang 23(1):327337

Article Google Scholar

Choma EF, Evans JS, Hammitt JK, Gmez-Ibez JA, Spengler JD (2020) Assessing the health impacts of electric vehicles through air pollution in the United States. Environ Int 144:106015. https://doi.org/10.1016/j.envint.2020.106015

Article CAS Google Scholar

Dai Q, Kelly JC, Gaines L, Wang M (2019) Life cycle analysis of lithium-ion batteries for automotive applications. Batteries 5. https://doi.org/10.3390/batteries5020048

Davis TM, Moos LP, Golchert NW (2012) Argonne National Laboratory site environmental report for calendar year 2011 (no. ANL-12/02). Argonne National Lab (ANL), Argonne

Book Google Scholar

Dhingra T, Sengar A, Sajith S (2022) A fuzzy analytic hierarchy process-based analysis for prioritization of barriers to offshore wind energy. J Clean Prod 345:131111. https://doi.org/10.1016/j.jclepro.2022.131111

Article Google Scholar

Duan L, Xia K, Feng T, Jia S, Bian J (2016) Study on coal-fired power plant with CO2 capture by integrating molten carbonate fuel cell system. Energy 117:578589

Article CAS Google Scholar

Ellingsen LA-W, Majeau-Bettez G, Singh B, Srivastava AK, Valen LO, Strmman AH (2014) Life cycle assessment of a lithium-ion battery vehicle pack. J Ind Ecol 18:113124. https://doi.org/10.1111/jiec.12072

Article CAS Google Scholar

Emissions GG (2011) Comparison of lifecycle greenhouse gas emissions of various electricity generation sources. https://www.worldnuclear.org/uploadedfiles/org/wna/publications/working_group_reports/comparison_of_lifecycle.pdf. Accessed June 2022

EPA (2022) Global Greenhouse Gas Emissions Data US EPA [WWW Document]. URL https://www.epa.gov/ghgemissions/global-greenhouse-gas-emissions-data (accessed 2.17.22)

Evtimov I, Ivanov R, Kadikyanov G, Staneva G (2018) Life cycle assessment of electric and conventional cars energy consumption and CO2 emissions. In: MATEC web of conferences, vol 234. EDP Sciences, p 02007

Google Scholar

Forman GS, Unnasch S (2015) Integration of non-fuel coproducts into the GREET model. Environ Sci Technol 49:43724380. https://doi.org/10.1021/es505994w

Article CAS Google Scholar

Franz S, Nasca A (2021) The environmental impact of electric vehicles: a novel life cycle-based evaluation framework and its applications to multi-country scenarios. J Clean Prod 315:128005. https://doi.org/10.1016/j.jclepro.2021.128005

Article CAS Google Scholar

Gaines L, Sullivan J, Burnham A, Belharouak I (2011) Life-cycle analysis of production and recycling of lithium ion batteries. Transp Res Rec 2252(1):5765. https://doi.org/10.3141/2252-08

Article Google Scholar

Goel S, Sharma R, Rathore AK (2021) A review on barrier and challenges of electric vehicle in India and vehicle to grid optimisation. Transp Eng 4. https://doi.org/10.1016/j.treng.2021.100057

Griffin M (2021) The future of work in the automotive industry: the need to invest inpeoplescapabilities and decent and sustainable work, International Labour Organisation. Retrieved from https://policycommons.net/artifacts/2434301/the-future-of-work-in-the-automotive-industry/3455893/ on 23 Jan 2023. CID: 20.500.12592/9q4gm6

Hall D, Lutsey N (2018) Effects of battery manufacturing on electric vehicle life-cycle greenhouse gas emissions. https://theicct.org/publication/effects-of-battery-manufacturing-on-electric-vehicle-life-cycle-greenhousegas-emissions/

Hausfather Z, Drake HF, Abbott T, Schmidt GA (2020) Evaluating the performance of past climate model projections. Geophys Res Lett 47(1):e2019GL085378

Article Google Scholar

Hawkins TR, Singh B, Majeau-Bettez G, Strmman AH (2013) Comparative environmental life cycle assessment of conventional and electric vehicles. J Ind Ecol 17(1):5364. https://doi.org/10.1111/j.1530-9290.2012.00532.x

Article CAS Google Scholar

Haynes VO (1976) Energy use in petroleum refineries (Vol. 5433). Oak Ridge National Laboratory. https://www.osti.gov/servlets/purl/7261027. Accessed June 2022

Helmers E, Dietz J, Hartard S (2017) Electric car life cycle assessment based on real-world mileage and the electric conversion scenario. Int J Life Cycle Assess 22:1530. https://doi.org/10.1007/s11367-015-0934-3

Article CAS Google Scholar

Helmers E, Dietz J, Weiss M (2020) Sensitivity analysis in the life-cycle assessment of electric vs. combustion engine cars under approximate real-world conditions. Sustainability 12. https://doi.org/10.3390/su12031241

Hertwich EG, Gibon T, Bouman EA, Arvesen A, Suh S, Heath GA, Bergesen JD, Ramirez A, Vega MI, Shi L (2015) Integrated life-cycle assessment of electricity-supply scenarios confirms global environmental benefit of low-carbon technologies. Proc Natl Acad Sci U S A 112:62776282. https://doi.org/10.1073/pnas.1312753111

Article CAS Google Scholar

IPCC (2014) Climate change 2014 synthesis report. Geneva, Szwitzerland, IPCC, pp 10591072

Google Scholar

Jordaan SM, Combs C, Guenther E (2021) Life cycle assessment of electricity generation: a systematic review of spatiotemporal methods. Adv Appl Energy 3:100058. https://doi.org/10.1016/j.adapen.2021.100058

Article Google Scholar

Kallitsis E, Korre A, Kelsall GH (2022) Life cycle assessment of recycling options for automotive Li-ion battery packs. J Clean Prod 371:133636. https://doi.org/10.1016/j.jclepro.2022.133636

Article CAS Google Scholar

Karbowski D, Rousseau A, Pagerit S, Sharer P (2006) Plug-in vehicle control strategy: from global optimization to real time application. In: 22th international electric vehicle symposium (EVS22), Yokohama

Ke W, Zhang S, He X, Wu Y, Hao J (2017) Well-to-wheels energy consumption and emissions of electric vehicles: mid-term implications from real-world features and air pollution control progress. Appl Energy 188:367377. https://doi.org/10.1016/j.apenergy.2016.12.011

Article CAS Google Scholar

Kim HC, Wallington TJ, Arsenault R, Bae C, Ahn S, Lee J (2016) Cradle-to-gate emissions from a commercial electric vehicle Li-ion battery: a comparative analysis. Environ Sci Technol 50(14):77157722. https://doi.org/10.1021/acs.est.6b00830

Article CAS Google Scholar

Kim Y, Kim H, Suh K (2021) Environmental performance of electric vehicles on regional effective factors using system dynamics. J Clean Prod 320. https://doi.org/10.1016/j.jclepro.2021.128892

Kobashi T, Yoshida T, Yamagata Y, Naito K, Pfenninger S, Say K, Takeda Y, Ahl A, Yarime M, Hara K (2020) On the potentialof Photovoltaics + Electric vehicles for deep decarbonization of Kyotos power systems: techno-economic-social considerations. Appl Energy 275. https://doi.org/10.1016/j.apenergy.2020.115419

Koroma MS, Costa D, Philippot M, Cardellini G, Hosen MS, Coosemans T, Messagie M (2022) Life cycle assessment of battery electric vehicles: implications of future electricity mix and different battery end-of-life management. Sci Total Environ 831:154859. https://doi.org/10.1016/j.scitotenv.2022.154859

Article CAS Google Scholar

Kumar R, Bharj RS, Bharj J, Singh GN, Sharma M (2021) Solar-based electric vehicle charging stations in India: A perspective. Energy Environ Sustain. https://doi.org/10.1007/978-981-16-0594-9_10

Article Google Scholar

Leach F, Kalghatgi G, Stone R, Miles P (2020) electric cars. Transp Eng 1:100005. https://doi.org/10.1016/j.treng.2020.100005

Article Google Scholar

Lewis AM, Kelly JC, Keoleian GA (2014) Vehicle lightweighting vs. electrification: life cycle energy and GHG emissions results for diverse powertrain vehicles. Appl Energy 126:1320

Article Google Scholar

Lijewski P, Ziolkowski A, Daszkiewicz P, Andrzejewski M, Gallas D (2018) Comparison of CO2 emissions and fuel consumption of a hybrid vehicle and a vehicle with a direct gasoline injection engine. In: IOP conference series: materials science and engineering, vol 421, No 4. IOP Publishing, p 042046

Google Scholar

Liu CM, Sandhu NK, McCoy ST, Bergerson JA (2020) A life cycle assessment of greenhouse gas emissions from direct air capture and Fischer-Tropsch fuel production. Sustain Energy Fuels 4:31293142. https://doi.org/10.1039/c9se00479c

Article CAS Google Scholar

Liu L (2020) Life cycle assessment of a lithium-ion battery pack for energy storagesystems : - the environmental impactof a grid-connected battery energy storage system (Dissertation). Retrieved from http://urn.kb.se/resolve?urn=urn:nbn:se:uu:diva-428627. Accessed June 2023

Lu Q, Wu P, Shen W, Wang X, Zhang B, Wang C (2016) Life cycle assessment of electric vehicle power batteryhttps://doi.org/10.4028/www.scientific.net/MSF.847.403

Malode S, Mohanta JC, Prakash R (2022) A review on life cycle assessment approach on thermal power generation. Mater Today: Proceedings 56:791798. https://doi.org/10.1016/j.matpr.2022.02.258

Article CAS Google Scholar

Masanet E, Chang Y, Gopal AR, Larsen P, Morrow WR III, Sathre R, Shehabi A, Zhai P (2013) Life-cycle assessment of electric power systems. Annu Rev Environ Resour. https://doi.org/10.1146/annurev-environ-010710-100408

Article Google Scholar

Mayyas A, Omar M, Hayajneh M, Mayyas AR (2017) Vehicles lightweight design vs. electrification from life cycle assessment perspective. J Clean Prod 167:687701. https://doi.org/10.1016/j.jclepro.2017.08.145

Article Google Scholar

Mehmeti A, Angelis-Dimakis A, Arampatzis G, McPhail SJ, Ulgiati S (2018) Life cycle assessment and water footprint of hydrogen production methods: from conventional to emerging technologies. Environ. https://doi.org/10.3390/environments5020024

Article Google Scholar

Messagie M (2014) Life cycle analysis of the climate impact of electric vehicles. J Life Cycle Assess 2014:14

Google Scholar

Nagarkatti A, Kolar AK (2015) Assessment of life cycle greenhouse gas emissions from coal fired power plants in India. Appl Mech Mater 704:487490

Article Google Scholar

Nemry F, Leduc G,MuozA (2009) Plug-in hybrid and battery-electric vehicles: state of the research and development and comparative analysis of energy and cost efficiency (no. JRC54699). Joint Research Centre (Seville site)

None N (2013) Life cycle greenhouse gas emissions from electricity generation, vol No. NREL/FS-6A20-57187. National Renewable Energy Lab (NREL), Golden

Book Google Scholar

Parmar T (2017) Life cycle impact assessment of production stages: LPG, Diesel and Petrol

Petrauskien K, Galinis A, Kliaugait D, Dvarionien J (2021) Comparative environmental life cycle and cost assessment of electric, hybrid, and conventional vehicles in Lithuania. Sustainability 13(2):957

Article Google Scholar

Porzio J, Scown CD (2021) Life-cycle assessment considerations for batteries and battery materials. Adv Energy Mater 11(33):2100771. https://doi.org/10.1002/aenm.202100771

Article CAS Google Scholar

Puig-Samper Naranjo G, Bolonio D, Ortega MF,Garca-MartnezM-J (2021) Comparative life cycle assessment of conventional, electric and hybrid passenger vehicles in Spain. J Clean Prod 291. https://doi.org/10.1016/j.jclepro.2021.125883

Qiao Q, Zhao F, Liu Z, Jiang S, Hao H (2017) Comparative study on life cycle CO2 emissions from the production of electric and conventional vehicles in China. Energy Procedia 105:35843595. https://doi.org/10.1016/j.egypro.2017.03.827

Article Google Scholar

Rajaeifar MA, Raugei M, Steubing B, Hartwell A, Anderson PA, Heidrich O (2021) Life cycle assessment of lithium-ion battery recycling using pyrometallurgical technologies. J Ind Ecol 25(6):15601571

Article CAS Google Scholar

Rokadiya S, Yang Z, Bandivadekar A (2019) Incentivizing electric vehicles to meet fuel consumption standards for passenger cars in India. The International Council on Clean Transportation (ICCT) white paper

Google Scholar

Samaras C, Meisterling K (2008) Life cycle assessment of greenhouse gas emissions from plug-in hybrid vehicles: implications for policy. Environ Sci Technol 42(9):31703176. https://doi.org/10.1021/es702178s

Article CAS Google Scholar

Sanguesa JA, Torres-Sanz V, Garrido P, Martinez FJ, Marquez-Barja JM (2021) A review on electric vehicles: technologies and challenges. Smart Cities 4(1):372404

Article Google Scholar

Sato FEK, Nakata T (2020) Energy consumption analysis for vehicle production through a material flow approach. Energies 13(9):2396. https://doi.org/10.3390/en13092396

Article CAS Google Scholar

Schulz-MnninghoffM, Bey N,NrregaardPU, Niero M (2021) Integration of energy flow modelling in life cycle assessment of electric vehicle battery repurposing: evaluation of multi-use cases and comparison of circular business models. Resour Conserv Recycl 174. https://doi.org/10.1016/j.resconrec.2021.105773

ereov M, tefanica J, Vitvarov M, Zakuciov K, Wolf P, Ko V (2020) Life cycle performance of various energy sources used in the Czech Republic. Energies 13(21):5833

Article Google Scholar

Shah B, Unnikrishnan S (2015) Environmental impacts of electricity generation case study from India using life cycle assessment approach. J Environ Res Dev 10(2):361

CAS Google Scholar

Shah B, Unnikrishnan S (2018) Sustainability assessment of gas-based power generation using a life cycle assessment approach: a case study from India. Manag Environ Qual an Int J 29:826841. https://doi.org/10.1108/MEQ-02-2018-0034

Article Google Scholar

Shi X, Wang X, Yang J, Sun Z (2016) Electric vehicle transformation in Beijing and the comparative eco-environmental impacts: a case study of electric and gasoline powered taxis. J Clean Prod 137:449460. https://doi.org/10.1016/j.jclepro.2016.07.096

Article CAS Google Scholar

Shrivastava S, Unnikrishnan S (2019) Review of life cycle assessment and environmental impacts from the oil & Gas sector. In 28th International Conference for the International Association of Management of Technology: Managing Technology for Inclusive and Sustainable Growth, IAMOT 2019. Excel India Publishers, pp. 972984

Singh U, Rao AB (2016) Techno-economic assessment of carbon mitigation options for existing coal-fired power plants in India. Energy Procedia 90:326335

Article CAS Google Scholar

Sulistyawati S, Iswara AP, Boedisantoso R (2020) Impacts assessment of crude oil exploration using life cycle assessment (LCA). In IOP Conf Ser Earth Environ Sci 506(1):012025. https://doi.org/10.1088/1755-1315/506/1/012025

Article Google Scholar

Temporelli A, Carvalho ML, Girardi P (2020) Life cycle assessment of electric vehicle batteries: an overview of recent literature. Energies 13. https://doi.org/10.3390/en13112864

Tivander J (2016) Environmental concerns of metals in Li-ion batteries Implications for recycling. Department of Energy and Environment of the Chalmers University of Technology (Sweden)

Tolomeo R, De Feo G, Adami R, Sesti Osso L (2020a) Application of life cycle assessment to lithium ion batteries in the automotive sector. Sustainability 12(11):4628. https://doi.org/10.3390/su12114628

Article CAS Google Scholar

Tolomeo R, De Feo G, Adami R,OssoLS (2020b) Application of life cycle assessment to lithium ion batteries in the automotive sector. Sustainability 12. https://doi.org/10.3390/su12114628

Turconi R, Boldrin A, Astrup T (2013) Life cycle assessment (LCA) of electricity generation technologies: overview, comparability and limitations. Renew Sust Energ Rev 28:555565

Article CAS Google Scholar

Unterreiner L, Jlch V, Reith S (2016) Recycling of battery technologiesecological impact analysis using life cycle assessment (LCA). Energy Procedia 99:229234

Article CAS Google Scholar

Vineyard D, Ingwersen WW (2017) A comparison of major petroleum life cycle models. Clean Technol Environ Policy 19(3):735747. https://doi.org/10.1007/s10098-016-1260-6

Article CAS Google Scholar

Wang F, Deng Y, Yuan C (2020) Life cycle assessment of lithium oxygen battery for electric vehicles. J Clean Prod 264. https://doi.org/10.1016/j.jclepro.2020.121339

Wang M, Han J, Elgowainy A (2016) The life-cycle analysis of petroleum fuels and biofuels with GREET. Argonne National Laboratory. https://ww2.arb.ca.gov/sites/default/files/classic/fuels/lcfs/lcfs_meetings/12132016wang.pdf. Accessed June 2022

Wong EYC, Ho DCK, So S, Tsang CW, Chan EMH (2021) Life cycle assessment of electric vehicles and hydrogen fuel cell vehicles using the greet modela comparative study. Sustainability 13. https://doi.org/10.3390/su13094872

Yudhistira R, Khatiwada D, Sanchez F (2022) A comparative life cycle assessment of lithium-ion and lead-acid batteries for grid energy storage. J Clean Prod 358:131999. https://doi.org/10.1016/j.jclepro.2022.131999

Article CAS Google Scholar

Zackrisson M,NordelfA, Wiktorsson M, Kurdve M,JnssonC, Rocha C, Christiansen K, Jarnehammar A, Johannisson W, Fransson K, Posner S, Zenkert D, Lindbergh G,AvellnL, Orlenius J, Hildenbrand J, Lampic G,ODwyerC, Berg H (2021) Life cycle assessment of electric vehicle batteries and new technologies

Zeng D, Dong Y, Cao H, Li Y, Wang J, Li Z, Hauschild MZ (2021) Are the electric vehicles more sustainable than the conventional ones? Influences of the assumptions and modeling approaches in the case of typical cars in China. Resour Conserv Recycl 167. https://doi.org/10.1016/j.resconrec.2020.105210.