The Green Revolution How Electric Vehicles Are Reshaping the Automotive Industry

Electric vehicle battery supply chain analysis 2021: How lithium-ion battery demand and production are reshaping the automotive industry

Sales and production of electric vehicles (EVs) continue to accelerate globally, with double-digit annual growth expected over the next decade. To keep the expansion and development of EVs charging ahead, vehicle manufacturers, automotive suppliers and governments are plugging in more investment to regional supply chain and gigafactory networks for lithium-ion batteries.

Lithium-ion battery technology is critical to improving the driving range of electric vehicles and to reducing the costs of plug-in, rechargeable powertrains compared to gasoline-powered vehicles. However, with demand for EVs rising faster than predicted before the Covid-19 pandemic, the supply and cost of materials like lithium and cobalt have tightened, while many vehicle manufacturers have become dependent on a few lithium-ion battery suppliers. Meanwhile, with a large share of the value chain based in Asia and especially China, carmakers and automotive suppliers are in a race to develop battery factories and supply chains across Europe and North America, too.

Download the battery supply chain reportBysigning-in orregistering to download you consent to receiving further information from us about this report and other related news, insights, intelligence and events. You also agree for us to share your contact information with our partners and sponsors who may contact you about their related products and services. For more information about how we use your data and your opt-out rights, please seehttp://ultimamedia.com/ultimamediapp.pdf

Trying to out giga Tesla OEMs including Tesla, Volkswagen Group, BMW, General Motors, Geely, Ford and many more are investing billions of dollars to secure lithium supply, diversify suppliers and to expand lithium-ion battery and battery pack production. Many vehicle manufacturers and lithium cell suppliers are planning battery plants that will be several times larger than the current largest global gigafactory, the Tesla Gigafactory 1 in Nevada (including Tesla, which is building a new gigafactory network that spans Texas, China and Germany).

Developing a robust and flexible EV battery supply chain will increasingly be a competitive advantage in the race for vehicle electrification. That will include securing upstream EV battery supplies like lithium, sourcing components such as electrode materials, anodes, cathode materials and electrolytes. It will mean maintaining supply for lithium cells through diverse supplier agreements. And it will also lead more automakers and suppliers to manufacture lithium-ion batteries at regional gigafactories or near to the production line for electric vehicles.

Download this updated report from Automotive from Ultima Media, the business intelligence arm of Automotive Logistics, in partnership with GEFCO and ABB, to understand more about the complex supply chain for lithium-ion batteries and to help make strategic gigafactory investment decisions to support electric car and truck manufacturing ambitions. The report features new forecasts of global and regional demand for lithium-ion batteries by gigawatt hours (GWh), data on major and emerging lithium-ion battery suppliers, gigafactory locations and insight into manufacturing and sourcing strategies for EV and plug-in electric vehicle (PHEV) batteries globally.

Download the report for data on demand, capacity and suppliers for lithium-ion batteries, including:

- Global passenger new vehicle powertrain forecast by type 2021-2040

- Global lithium battery demand and production capacity forecast 2020-2030

- Top battery cell company analysis including lithium-ion factory locations and capacity, battery supply agreements and EV material suppliers

- Evolving automaker strategies for lithium-ion battery supply and production, including Tesla, Volkswagen Group, General Motors, Ford and Stellantis

Download EV battery supply chain analysis 2021

The rise of the lithium value chain The analysis reveals an explosion of investment and planned capacity in the supply chain for lithium-ion batteries. Vehicle manufacturers like Tesla and Volkswagen are working more closely on the mining of lithium and production of electrolyte and cathode materials. Meanwhile, there are at least 100 new gigafactory facilities in the pipeline across major automotive manufacturing regions in Asia, Europe and North America and even that may not provide enough battery factory capacity to meet electric car and truck demand.

Rising demand and production for lithium-ion batteries is leading to the emergence of major battery cell suppliers, including LG Energy Solution, SK Innovation, CATL and Panasonic, along with startup EV battery players like Northvolt, Farasis, SVOLT and many more across the supply chain. At the same time, OEMs are diversifying their suppliers and ramping up production of lithium-ion batteries, with OEMs including Volkswagen Group, General Motors, Stellantis and Ford looking to the Tesla and Panasonic model of joint venture lithium battery production or even looking to in-house lithium mining and gigafactory operations.

Download this free, 150+ page report into the changing supply chains for automotive lithium-ion batteries, including rankings of battery suppliers, factory locations, changing regulations and mapping of the complex supply chain for lithium and electric car materials and recycling.

Extensive databases are also available for global battery gigafactory investments, EV and hybrid assembly plants as well as fast-changing OEM-battery supplier relationships.

Data and analysis of upstream and downstream supply chain for EV batteries, including:

- Raw material and mineral supplier analysis for lithium-ion batteries: lithium, cobalt, nickel, manganese

- Component supplier analysis for lithium-ion batteries: cathodes materials, anodes, electrolytes, separators

- Battery management systems (BMS)

- Thermal management systems (TMS)

- Battery pack cases

- Disruptive technologies including solid-state battery, sodium-ion and alternatives for high energy density

- Automotive battery re-use and recycling companies

Download EV battery supply chain analysis 2021

| Key battery cell company overview and analysis, including: |

|---|

| Panasonic |

| Dynavolt |

| Farasis |

| BAK |

| Envision AESC |

| Samsung SDI |

| SK Innovation |

| Guoxuan |

| CATL |

| SVOLT |

| SAFT |

| LG Energy Solution |

| Northvolt |

| Primearth EV |

| BYD |

| Tesla |

| and many more |

In Partnership

ABB is a leading global technology company that energises the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABBs success is driven by about 105,000 talented employees in over 100 countries.www.abb.com

ABB Robotics & Discrete Automation is a pioneer in robotics, machine automation and digital services, providing innovative solutions for a diverse range of industries, from automotive to electronics to logistics. As one of the worlds leading robotics and machine automation suppliers, it has shipped more than 500,000 robot solutions. ABB helps customers of all sizes to increase productivity, flexibility and simplicity and to improve output quality. ABB supports their transition towards the connected and collaborative factory of the future. ABB Robotics & Discrete Automation employs more than 10,000 people at over 100 locations in more than 53 countries.www.abb.com/robotics

GEFCO has specialised in automotive logistics for nearly 70 years, maintaining a presence in 45 countries, with 13,000 employees and a turnover of 4.4 billion ($5 billion). GEFCO is number one in the European finished vehicle market and ranks among Europes top ten leading transport and logistics groups. GEFCO has a presence in six continents and its operations cover a total of 150 countries. With a large workforce around the world, GEFCO thrives on the challenges of the global automotive industry.

Today GEFCO covers every aspect of automotive logistics for car manufacturers, parts suppliers and the two-wheeler industry, both inbound and outbound. The companys vision is to add value and generate savings for its automotive customers through multimodal supply chain engineering and optimisation. For more on GEFCOs supply chain solutions, including those supporting electric vehicle and battery supply chains, visit: gefco.net/en/industries/automotive

To download this report, clickthe link in the downloads box below.

By downloading the report you consent to receiving further information from us about this report and other related news, insights, intelligence and events. You also agree for us to share your contact information with our partners and sponsors who may contact you about their related products and services. For more information about how we use your data and your opt-out rights, please see:http://ultimamedia.com/ultimamediapp.pdf

Green technology and the future of the automotive industry

With rising car emissions, countries are implementing strict regulations to minimize the environmental impact of the

automotive industry.

From production to disposal, the industry's contribution to climate change and CO2 emissions remains a pressing concern. Undoubtedly, moving towards a greener, more ecological solution presents an ideal business move for automobile manufacturers, offering significant potential to drive a more sustainable future.

Resultantly, companies are actively seeking to launch their

electric vehiclein the market. Recent statistics highlight the transformative impact of green energy on the automotive industry, with electric vehicle (EV) sales witnessing remarkable growth.

According to the International Energy Agency, a record 10 million electric cars were sold globally in 2022, up from 6.9 million in 2021. China, Europe, and the US claim most of the market share.

India, though a little behind in electric cars, registered

EV salesacross all vehicle segments for 12,43,258 units in 2022, a 154% increase over 2021 sales, with electric two-wheelers accounting for the most sales.

This surge in demand for greener transportation signifies a paradigm shift towards a more sustainable future for the automotive industry in India.

Evidently, top EV companies like

Teslaand

BYDhave also started protecting their technologies in India.

In the last decade, Tesla has filed and acquired around 30 patents related to EV batteries. At the same time, BYD has filed 125 patents. While Tesla is pushing to establish in India, BYD seems to be growing fast in the last few years.

Tesla had even registered a company named Tesla India Motors And Energy in Bengaluru but didnt process further due to heavy import duties. Ever since theres been to and fro talks about it. However, PM Modis recent meeting with Elon Musk during his US visit shows positive signs that Tesla will soon set up their base in India.

On the flip side, BYD made an impressive debut in the Indian market with their first electric SUV, the Atto 3. Within two months of its launch in November last year, BYD successfully delivered 700 units. With an ambitious target of selling 15,000 units this year, BYD intends to become the second-largest electric vehicle (EV) seller and solidify its foothold in India's burgeoning EV market.

However, India-based Industry giants such as

Tata Motors, which counts Jaguar Land Rover among its subsidiaries,

Mahindra and Mahindra, and Ola are maintaining a strong foothold in the Indian market as foreign companies seek the potential for setting up manufacturing units for both EV and its components in India.

Tata alone was accountable for 85% of the EV sales in India in 2022, followed by MG Motor India. The company has filed over 70 patents across various countries in EV, Hybrid, as well as EV charging stations and devices.

EV Startups like Ather Energy, with 23 patents in the home country, are making a mark in the EV sector with their indigenous innovations. Using Cloud IoT Core and BigQuery, Ather Energy created an intelligent electric scooter with route optimization and predictive maintenance to help people in India's dynamic economy. Their synergy with Cloud IoT solutions resulted in a one-of-

a-kind mobility platform for India and beyond.

As countries intensify efforts to combat climate change, regulations are being enforced to minimize the environmental impact of car emissions.

Automakers have a unique opportunity to lead the charge toward a greener future by adopting eco-friendly solutions. Even OEMs are actively innovating environmentally friendly vehicle parts. GiTi Radial Tire (Anhui), a China-based global supplier, is working on a super abrasive high-mechanic fuel-saving environmental protection VAN tire.

By prioritizing sustainability, the automotive industry can significantly reduce CO2 emissions and pave the way for cleaner transportation.

India's pioneering automotive companies, alongside their global counterparts, have set their sights on harnessing the immense potential of

green technologywithin the automotive sector. As the momentum for sustainable transportation grows, India's automotive industry stands poised to lead the charge toward a greener tomorrow.

The EV Revolution: How Electric Vehicles Are Reshaping the Automotive Industry

Electric vehicles (EVs) have been gaining significant traction in recent years, as the world shifts towards more sustainable and environmentally-friendly transportation options. The rise of EVs is not only reshaping the automotive industry but also transforming the way we think about transportation and energy consumption.

The Environmental Impact of Electric Vehicles

One of the main driving forces behind the EV revolution is the need to reduce greenhouse gas emissions and combat climate change. Unlike traditional internal combustion engine vehicles, EVs produce zero tailpipe emissions, helping to improve air quality and reduce pollution in urban areas. By transitioning to electric vehicles, we can significantly reduce our carbon footprint and mitigate the harmful effects of fossil fuel consumption.

Furthermore, the widespread adoption of EVs will also contribute to the decarbonization of the energy sector. As renewable energy sources such as solar and wind power become more prevalent, charging EVs with clean energy will further reduce the overall carbon emissions associated with transportation.

Technological Advancements in Electric Vehicles

The EV revolution has spurred significant advancements in technology, leading to the development of more efficient and reliable electric vehicles. Battery technology, in particular, has seen remarkable progress, with longer range and faster charging capabilities becoming the norm.

Moreover, advancements in autonomous driving technology and connectivity have made electric vehicles more appealing to consumers. Features such as regenerative braking and smart charging systems have improved the efficiency and convenience of owning an EV, making them a viable alternative to traditional vehicles.

The Economic Impact of Electric Vehicles

As the demand for electric vehicles continues to grow, the automotive industry is undergoing a major transformation. Traditional automakers are investing heavily in EV production and research, while new players are entering the market with innovative electric vehicle designs.

This shift towards electric vehicles has also led to the creation of new job opportunities in the renewable energy and electric vehicle sectors. From manufacturing batteries to developing charging infrastructure, the EV revolution is driving economic growth and creating a more sustainable future.

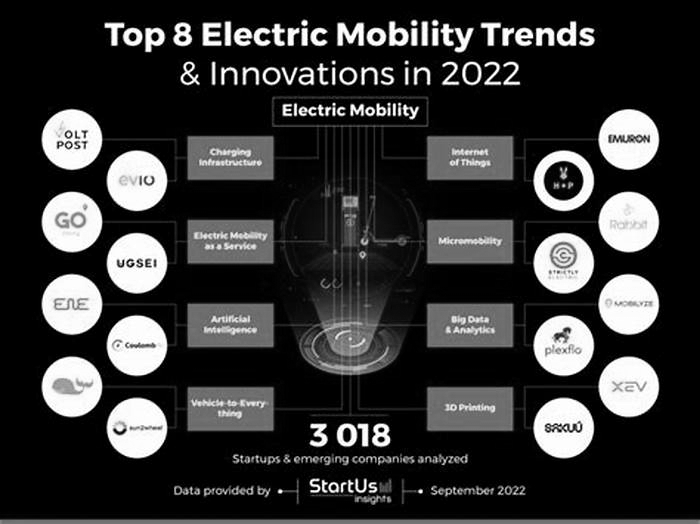

Challenges and Opportunities

While the EV revolution presents numerous benefits, it also comes with its fair share of challenges. The limited availability of charging infrastructure is one of the main barriers to widespread EV adoption. However, governments and private companies are investing in the expansion of charging networks to address this issue.

Another challenge is the affordability of electric vehicles. Although the cost of EVs has been decreasing over the years, they are still more expensive than traditional vehicles. However, as technology advances and economies of scale come into play, the price of EVs is expected to become more competitive.

Despite these challenges, the EV revolution presents significant opportunities for innovation and growth. From developing more efficient batteries to improving charging infrastructure, there is immense potential for technological advancements that will further accelerate the adoption of electric vehicles.

The Future of Electric Vehicles

The future of electric vehicles looks promising. With governments around the world setting ambitious targets for reducing carbon emissions, the demand for electric vehicles is expected to skyrocket in the coming years.

As the EV revolution continues to unfold, we can expect to see more affordable electric vehicles with longer ranges, faster charging times, and improved performance. The integration of renewable energy sources and smart grid technologies will further enhance the sustainability and efficiency of electric vehicles.

In conclusion, the EV revolution is reshaping the automotive industry and paving the way for a more sustainable and cleaner future. Electric vehicles not only offer environmental benefits but also drive technological advancements and economic growth. As we move towards a greener transportation system, electric vehicles will play a crucial role in reducing our dependence on fossil fuels and mitigating the impacts of climate change.