Why are EV batteries bad for the environment

The Environmental Impact of Lithium Batteries

During the Obama-Biden administration, hydraulic fracturing was accused of causing a number of environmental problemsfaucets on fire, contamination of drinking water, etc.but the administrations own Environmental Protection Agency could not validate those accusations. Now Biden is planning to transition the transportation sector to electric vehicles that are powered by lithium batteries and require other critical metals where China dominates the market. Mining and processing of lithium, however, turns out to be far more environmentally harmful than what turned out to be the unfounded issues with fracking.

In May 2016, dead fish were found in the waters of the Liqi River, where a toxic chemical leaked from the Ganzizhou Rongda Lithium mine. Cow and yak carcasses were also found floating downstream, dead from drinking contaminated water. It was the third incident in seven years due to a sharp increase in mining activity, including operations run by Chinas BYD, one of the world biggest supplier of lithium-ion batteries. After the second incident in 2013, officials closed the mine, but fish started dying again when it reopened in April 2016.

Lithium prices doubled between 2016 and 2018 due to exponentially increasing demand. The lithium ion battery industry is expected to grow from 100 gigawatt hours of annual production in 2017 to almost 800 gigawatt hours in 2027. Part of that phenomenal demand increase dates back to 2015 when the Chinese government announced a huge push towards electric vehicles in its 13th Five Year Plan. The battery of a Tesla Model S, for example, has about 12 kilograms of lithium in it; grid storage needed to help balance renewable energy would need a lot more lithium given the size of the battery required.

Processing of Lithium Ore

The lithium extraction process uses a lot of waterapproximately 500,000 gallons per metric ton of lithium. To extract lithium, miners drill a hole in salt flats and pump salty, mineral-rich brine to the surface. After several months the water evaporates, leaving a mixture of manganese, potassium, borax and lithium salts which is then filtered and placed into another evaporation pool. After between 12 and 18 months of this process, the mixture is filtered sufficiently that lithium carbonate can be extracted.

South Americas Lithium Triangle, which covers parts of Argentina, Bolivia and Chile, holds more than half the worlds supply of the metal beneath its salt flats. But it is also one of the driest places on earth. In Chiles Salar de Atacama, mining activities consumed 65 percent of the regions water, which is having a large impact on local farmers to the point that some communities have to get water elsewhere.

As in Tibet, there is the potential for toxic chemicals to leak from the evaporation pools into the water supply including hydrochloric acid, which is used in the processing of lithium, and waste products that are filtered out of the brine. In Australia and North America, lithium is mined from rock using chemicals to extract it into a useful form. In Nevada, researchers found impacts on fish as far as 150 miles downstream from a lithium processing operation.

Lithium extraction harms the soil and causes air contamination. In Argentinas Salar de Hombre Muerto, residents believe that lithium operations contaminated streams used by humans and livestock and for crop irrigation. In Chile, the landscape is marred by mountains of discarded salt and canals filled with contaminated water with an unnatural blue hue. According to Guillermo Gonzalez, a lithium battery expert from the University of Chile, This isnt a green solution its not a solution at all.

China isamong the five top countrieswith the most lithium resources andit has been buyingstakes in mining operations in Australia and South America where most of the worlds lithium reserves are found.ChinasTianqi Lithiumowns51 percentof the worlds largest lithium reserve in Australia, giving it a controlling interest.In 2018, thecompany became the second-largest shareholder inSociedadQumicay Minerathe largest lithium producer in Chile.Another Chinese company,GanfengLithium, has a long-term agreement to underwrite all lithium raw materials produced byAustralias Mount Marion minethe worlds second-biggest,high-grade lithium reserve.

Recycling Lithium-Ion

In Australia, only two percent of the countrys 3,300 metric tons of lithium-ion waste is recycled. Unwanted MP3 players and laptops often end up in landfills, where metals from the electrodes and ionic fluids from the electrolyte can leak into the environment.

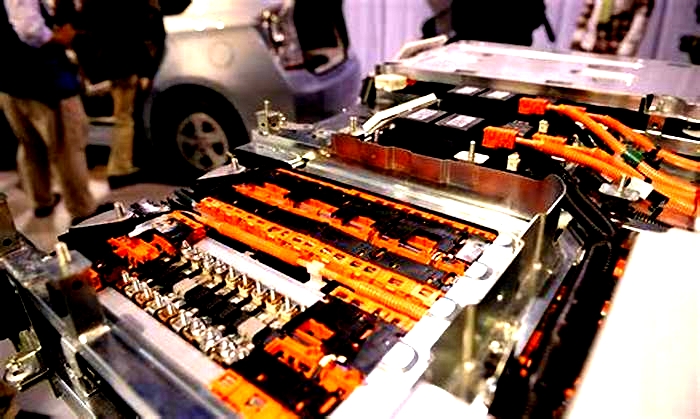

Because lithium cathodes degrade over time, they cannot be placed into new batteries. Researchers are using robotics technology developed for nuclear power plants to find ways to remove and dismantle lithium-ion cells from electric vehicles. There have been a number of fires at recycling plants where lithium-ion batteries have been stored improperly, or disguised as lead-acid batteries and put through a crusher. Not only have these batteries burned at recycling plants, but auto makers are seeing battery-related fires leading to vehicle recalls and safety probes. In October, U.S. safety regulators opened a probe into more than 77,000 electric Chevy Bolts after two owners complained of fires that appeared to have begun under the back seat where the battery is located.

Because manufacturers are secretive about what goes into their batteries, it makes it harder to recycle them properly. Currently, recovered cells are usually shredded, creating a mixture of metal that can then be separated using pyrometallurgical techniquesburningwhich wastes a lot of the lithium. Alternative techniques, including biological recycling where bacteria are used to process the materials, and hydrometallurgical techniques which use solutions of chemicals in a similar way to how lithium is extracted from brine are being investigated.

It is estimated that between 2021 and 2030, about 12.85 million tons of EV lithium ion batteries will go offline worldwide, and over 10 million tons of lithium, cobalt, nickel and manganese will be mined for new batteries. China is being pushed to increase battery recycling since repurposed batteries could be used as backup power systems for Chinas 5G stations or reused in shared e-bikes, which would save 63 million tons of carbon emissions from new battery manufacturing.

Cobalt Extraction Also Poses Environmental Problems

Cobalt is found in huge quantities in the Democratic Republic of Congo and central Africa where it is extracted from the ground by hand, using child labor, without protective equipment. China ownseight of the 14 largest cobalt minesin the Democratic Republic of Congo andthey accountfor about half of the countrys output. While China hasonly 1 percentof the worlds cobalt reserves, it dominates in the processing of raw cobalt. The Democratic Republic of Congo is the source of over two-thirds of global cobalt production, but China hasover 80 percentcontrol of the cobalt refining industry, where raw material is turned into commercial-grade cobalt metal.

Like lithium, the price of cobalt has quadrupled in the last two years.

Conclusion

Environmentalists expressed unfounded concerns about fracking, but they need to be worried about replacing fossil fuels in the transportation and electric generating sector with electric vehicles and renewable energy where lithium, cobalt and other critical metals are needed to produce these technologies. Mining, processing, and disposing of these metals can contaminate the drinking water, land and environment if done improperly as seen from several examples. And, since China dominates the global market, it just switches what once was U.S. reliance on the Middle East to U.S. reliance on the Peoples Republic.

Are electric car batteries bad for the environment?

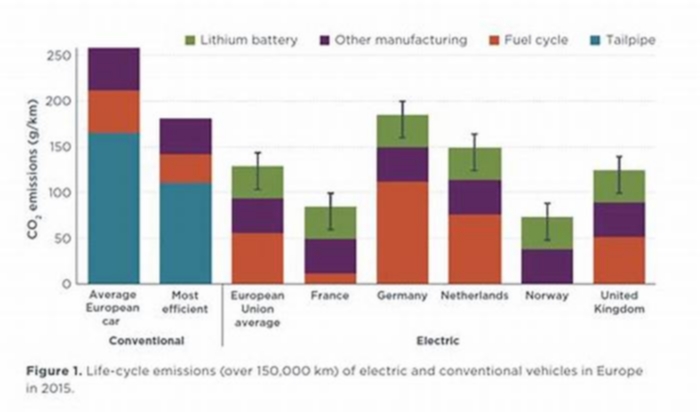

However, the production of batteries for EVs does present some environmental challenges. Some studies have shown that the manufacturing of a typical EV battery can result in higher carbon emissions compared to gasoline cars. This is due to the significant amount of energy required for the procurement of raw materials and the manufacturing process itself.

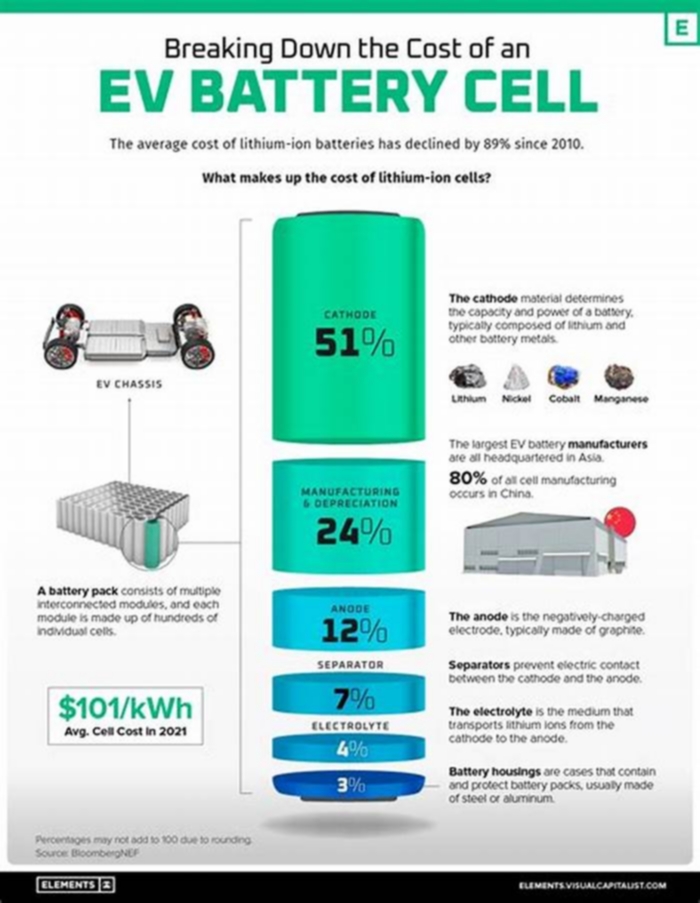

The majority of this energy consumption is linked to the production of the battery, which requires the extraction of rare and challenging-to-source materials such as lithium, cobalt, and manganese.

The sustainability of electric vehicle batteries

While the current production processes for EV batteries are not yet as sustainable as we would like, their clean operation over the life of the vehicle more than compensates for the initial environmental impact. It is essential that the industry continues to work towards making battery production more sustainable and transition to clean energy sources.

In this article, we will delve deeper into the environmental impact of gathering the raw materials for EV batteries, examine the rising alternatives, and explain why driving electric remains a more sustainable option than driving a gasoline car, even with the current challenges.

The rise of EVs as a sustainable alternative

Drivers around the world are becoming more aware of their environmental impact. According to our research in collaboration with Ipsos, 62 percent of the general public says that reducing CO2 emissions in transport is important, and 7 out of 10 EV drivers cite environmental considerations as decisive when buying a car.

Its no surprise, then, that electric vehicles are gaining in popularity.

While EVs produce little to no emissions while driving, their production, and in particular their battery, can have a significant environmental impact.

Lets explore in more detail how EV batteries, and the raw materials they contain, can be less environmentally friendly than they may seem.

Environmental impact of battery production and disposal

Electric car batteries are complex components containing many rare earth elements (REE), like lithium, nickel, cobalt, and graphite. As their name suggests, these materials are difficult to find and extract, requiring intensive mining and even some polluting processes to separate them from the soil. This is why producing EV batteries can be environmentally challenging.

EV battery production

An EV battery is made up of thousands of rechargeable lithium-ion cells connected to form the battery pack. Beyond the raw materials that make up its cells, an EV battery needs many more hardware and software components to make it functional. Lets take a look at the environmental impact of producing an electric vehicle battery.

EV battery raw materials

The primary materials that make up an EV battery are lithium, manganese, and cobalt. A report by Nature estimates that a typical EV battery uses about 8 kilograms of lithium, 14 kilograms of cobalt, and 20 kilograms of manganese.

Lets explore below each materials mining process and its environmental impact.

Lithium-ion

Although there are other EV battery chemistries, lithium-ion cells are by far the most popular, thanks to their cost-efficiency and relatively high energy density, offering an optimal trade-off between electricity storage capacity and price.

Lithium-ion mining

Lithium is mainly produced from salt flats or underground brine reservoirs, with most of the production concentrated in South America (namely Bolivia, Argentina, and Chile) and China.

Extracting lithium from the brine is fairly straightforward and is done by evaporating the water to leave behind a lithium-rich solution.

Lithium minings environmental impact

Because of this evaporation process, lithium mining uses a large amount of groundwater that gets lost in the process. This can deprive local communities of drinking water and harms farming by reducing the water available for irrigation especially given that most of the worlds lithium is extracted in arid regions with scarce water supplies in the first place.

On top of that, the remaining liquid left after lithium is extracted can contain toxic or radioactive elements and needs to be cleaned and stored before it can be released.

Cobalt

Besides lithium, cobalt is an often-cited culprit in EV batteries environmental and social impact. Cobalt is currently one of the main components of an EV batterys cells.

Cobalt mining

Cobalt is produced as a byproduct of copper and nickel mining but can also be mined directly, with Australia and the Democratic Republic of the Congo (DRC) being the main producers.

Cobalt minings environmental impact

Cobalt is perhaps one of the most problematic materials used in electric vehicles, both environmentally and socially. Cobalt mines produce toxic residues that can leach into the environment, poisoning groundwater and harming nearby communities. Additionally, smelting cobalt ore produces fumes with a high concentration of sulfur oxide and other air pollutants.

On top of their environmental impact, cobalt mines also raise labor concerns. With little formal regulation and oversight, workers in cobalt mines are often underpaid and lack adequate protective equipment, tools, and training. These dangerous conditions create problematic labor practices, which can lead to injury or even death.

To address these unfavorable circumstances, many leading automobile companies have made a commitment to obtain cobalt, graphite, and lithium from reliable and traceable sources. Meanwhile, battery producers are moving away from using cobalt and focusing more on materials that are easily accessible and have fewer issues, such as nickel or iron. Innovative studies on solid-state batteries hold the potential to completely eliminate the use of cobalt and significantly enhance the capacity and efficiency of new batteries.

Manganese

Compared to lithium and cobalt, manganese is often overlooked in the discussion about the raw materials needed for EV battery production. That said, it is a critical component in electric car batteries, and demand for it has risen considerably in recent years.

Manganese mining

Manganese is the fifth most abundant metal on Earth and is often found alongside iron deposits. Manganese is usually mined in open pit mines, with around 80% of manganese production coming from South Africa. Australia, China, India, Ukraine, and Brazil also produce significant shares of the metal.

Manganese minings environmental impact

Because of its mining in open pits, manganese extraction can cause substantial air pollution, especially in dry areas where dust from mining can rise easily. Additionally, manganese can pollute the soil and water supply, including by introducing other chemical elements.

The rise of LFP batteries

Given the problematic sourcing of many materials used in EV batteries, manufacturers are actively looking for new, environmentally and socially friendly solutions for producing batteries. One such alternative is lithium iron phosphate (LFP or Li-FP) technology, which uses iron instead of cobalt.

Compared to lithium-ion (Li-ion), LFP batteries have a number of advantages and challenges. Their main drawback, which has historically limited their use in EVs, is their lower energy density, meaning they tend to be less efficient and have a shorter range than Li-ion batteries.

That said, LFP batteries are also much easier (and thus cheaper) to produce, using much more commonly available materials. They are also more heat-resistant than Li-ion batteries and tend to have a longer lifespan.

EV manufacturers are already using LFP batteries, with Chinese manufacturers leading the way in LFP batteries. Still, Western companies are also adopting LFP technology, with Tesla, for example, reporting that half of its cars are already using cobalt-free LFP batteries.

Environmental impact of charging and driving electric cars

Because they dont burn gasoline or diesel to fuel their engines, the main environmental impact of electric cars comes from their manufacturing, and in particular, their battery. Of course, how sustainable an EV is for everyday use depends on how the electricity used to charge it is generated.

An EV powered by renewable sources will have a much lower impact than an EV powered by electricity generated using coal or natural gas. Still, on average, an EV reaches parity in terms of emissions with a combustion car engine after around 33,000 km on the road.

How sustainable are EV batteries really?

While EV battery production currently contends with some negative environmental and social impacts, new extraction processes, battery chemistries, and materials are paving the way for a more sustainable future.

Despite the widespread utilization of battery technology, its application as a power source for electric vehicles is still in its early stages. As costs continue to decrease and advancements are made, policymakers and industry leaders have a duty to enhance the working conditions related to the mining and production of batteries.

Of course, the impact of producing an electric car will never be zero, so reusing and recycling old EV batteries is critical for ensuring the materials they contain remain useful for as long as possible. Thankfully, its worth remembering that throughout their life, EVs are much more sustainable than gas-powered vehicles.EV batteries are currently expected to last about 15-20 years and can be reused and recycled to recover most of the raw materials they contain.